sheet metal simulation software Italia - Sheet Metal Forming Software - Ansys Limitless Welding And Fabrication, LLC offers hydraulic repair services, custom welding services & much more in Farmville, NC. Contact us today for a free estimate.Iron Clad Fabrication serves the greater Boise area and beyond with mobile on-site service for metal fabrication, welding and plasma cutting.

0 · stamping software

1 · stamping simulation

2 · simufact forming

3 · forming suite download with crack

4 · forging simulation software list

5 · esi pam stamp

6 · autoform engineering india pvt ltd

7 · altair inspire form

To weld copper, use clean, oxygen-free copper, which will retain its bronze color after welding, unlike copper alloys. You'll also want to use either argon or helium gas. Since copper has a high thermal conductivity, you'll need to .

Ansys Forming is an all-in-one forming simulation software built to digitally design and validate every step of the sheet metal forming process with speed and accuracy. Learn More. Validate .

Deutschland - Sheet Metal Forming Software - AnsysFrance - Sheet Metal Forming Software - Ansys

Italia - Sheet Metal Forming Software - Ansys

United Kingdom - Sheet Metal Forming Software - AnsysIndia - Sheet Metal Forming Software - AnsysOptimize the manufacturing process setting up single and multistage metal forming virtual tryout tools. The fast and scalable incremental solver supports forming and trimming, giving the ability to accurately analyze material flow, .

Create reliable and accurate virtual manufacturing realities with a wide range of simulation software, including metal forming, assembly & joining, and additive manufacturing, aiming at optimising manufacturing processes during design.Dynaform’s sheet metal forming simulation software makes it possible to uncover design flaws early in the process. Using the various modules engineers can more-fully evaluate alternative–and unconventional–designs. Doing so helps ensure .FormingSuite® is our premier software package for sheet metal forming. OEMs and suppliers worldwide use FormingSuite®to optimize the design, feasibil.

The software truly offers multiple benefits that can enhance or complement sheet metal forming. Sheet metal manufacturing shops are typically small- to medium-sized businesses that are looking to be as efficient as . Sheet metal simulation is a versatile tool that can benefit a diverse range of industries, including aerospace, automotive, and medical. . In addition to its efficiency and cost-effectiveness, metal stamping simulation software .Almacam Bend, CAD/CAM software for sheet metal bending. A complete CAD/CAM solution dedicated to the bending process. Plan a demo. . Using powerful, realistic and full 3D simulation tools, the application defines bend .Advanced simulation software orchestrates metal forming, unlocking the art of successful cold forming, hot forging, rolling, and stamping. Ready to get started? . Different methods of sheet metal forming can be used depending on the geometry of the desired part. Based on the characteristics of each deformation process, the forming engineer .

Overview. Bend-O-Matic is a revolutionary professional software package to determine Initial Unfolded Length.. It is an integral and indispensable part of Sheet Metal Bending operations, that will not only automate and speed up the numerous / repetitive calculations and drafting but also help you in achieving the same, with the maximum degree of accuracy and efficiency, thereby . Why Dynaform’s FS Module over other sheet metal forming simulations software? Dynaform’s FS Module couples ETA’s 40 years of experience in the stamping industry with the most reliable and realistic simulation solver, LS-DYNA. The FS module provides an efficient and streamlined workflow to set up your process.

stamping software

MBend simulates and performs collision detection for the part with all elements of the machine, i.e., fingers, tools, part, and machine frame. The simulation is done dynamically, displaying overbending and spring back, as well as finger movement between bends. In addition, MBend can show the part handling – the movement of the part between bends. This is useful for viewing .AnsysForm is a LS-DYNA based sheet metal forming simulation software, supporting formability analysis, iterative trimline development and iterative springback compensation functions. Forming Simulation Technologies(FST) provides finite element analysis consulting services, software distribution, and training in North American. .AutoForm’s software solutions form a comprehensive platform for the engineering, evaluation and improvement of the sheet metal forming and BiW assembly processes. This platform allows for full digitalization, seamless information and data flow, and integration of Industry 4.0 standards.Precision Sheet Metal Fabrication Machinery | RAS Systems / Products / Software / Bending 4.0. . Office software creates a program in less than one minute, and in addition visualizes the bending sequence in a 3D simulation. The software algorithms used to create the bending programs implement the expertise of hundreds of programmers. This not .

electric rc car tool box

Sheet metal forming simulation software finds applications across various industries due to its ability to enhance productivity and reduce costs and decrease lead times. In the automotive and land transportation industries, it is a widely accepted solution and extensively used to validate the manufacturability and part quality of sheet metal . Die System Simulation Software with New Interface, Set-Up-Time Reduction. With an all-new user interface, the Dynaform 6.0 die system simulation software enables users to quickly conduct sheet metal stamping simulations to estimate the blank cost and formability of stamping parts via guided process wizards.

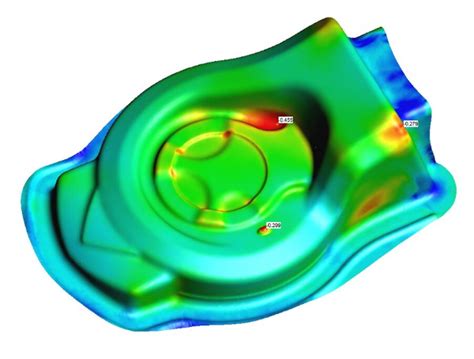

Today the metal forming industry is making increasing use of simulation to evaluate the performing of dies, processes and blanks prior to building try-out tooling. Finite element analysis (FEA) is the most common method of simulating sheet metal forming operations to determine whether a proposed design will produce parts free of defects such as fracture or wrinkling.

electric quad floor boxes for light pole

stamping simulation

Sheet metal engineering on demand. Fast track your tooling projects with product, tooling, production, or planning & bidding. . The dimple was drawn and, through our simulation, we were able to successfully reduce the process to six steps in order to minimize the thinning percentage to the required level. The precut areas were then developed .The methodology of simulating a sheet metal stamping process has become a formality, thanks to continuous advancements in simulation software, and more specifically AutoForm simulation technology. Sheet metal stamping simulation .Schimatari Viotias, 32009, Kormatzini Area 0030 22620 58675 [email protected] . ΑΡ. Γ.Ε.ΜΗ : 084207102000 General Electronic Commercial Registry (G.E.MI .

Engineering Technology Associates, Inc. (ETA) announces the launch of Dynaform 7.2, the latest version of their leading sheet metal forming simulation software. Building on the robust capabilities of its predecessor, Dynaform 7.2 introduces a range of new features and enhancements designed to further streamline and optimize the simulation of .

Troy, Michigan: Engineering Technology Associates, Inc. (ETA) proudly announces the launch of Dynaform 7.2, the latest version of their leading sheet metal forming simulation software.Building on the robust capabilities of its predecessor, Dynaform 7.2 introduces a range of new features and enhancements designed to further streamline and optimize the simulation of .Engineering Simulation Laboratory – Using leading-edge simulation software enables us to quickly and accurately create, analyze and optimize complex physical systems – from initial . (Finite Element) Simulation: Sheet Metal Forming, Hot Forging, Open Die Forging, Roll Forming, Extrusion and Heat Treatment with Ansys, Abaqus, LS-Dyna and .Engineers and manufacturers may model and evaluate the sheet metal forming process with the help of Hexagon MSC’s robust software solution, FTI Sheet Metal Forming Simulation. It provides an extensive feature set and tool set created especially for .

Sheet Flow Simulation for Sheet Metal Die Optimization Using Simcenter 3D Software July 2024 International Journal for Research in Applied Science and Engineering Technology 12(VII):440-444

Learn more about sheet metal design software resources, products, and tutorials. NEW - Professional Fusion Trial: Get 30-day free access to advanced features including probing, rotary milling, surface finishing, and more . Easy to use simulation capabilities.QForm is a professional engineering software used for simulation, analysis and optimization of metal forming processes providing excellent reliability. It covers the essential needs in metal forming simulation for large and small forging companies as well as .

It is remarkable to look back and see how far sheet metal forming simulation software has developed. Reflecting from personal experiences, I started with LSDYNA based software around the year 2000, which required many, many hours of meshing, mesh repair, and manual inputs of tooling travel curves (amongst many other tedious inputs) before a simulation could be sent for .FormingSuite® is our premier software package for sheet metal forming. OEMs and suppliers worldwide use FormingSuite®to optimize the design, feasibility and costing of sheet metal components. . Virtual prove out analysis simulation for sheet metal stamping, FTI FASTIncremental is a user-friendly, 3D explicit incremental analysis solution .RADAN is a CAD CAM solution for sheet metal cutting, providing applications for punching, profiling and bending. Product enquiry. . Discover services and support for our CAD CAM and CNC simulation software solutions, including training, applications support and software maintenance agreements.Digital Design Solutions - Offering Blank Size Engineering Sheet Metal Simulation Software, Free Demo/Trial Available, For Windows at Rs 600000/year in Gurgaon, Haryana. Also find Sheet Metal Forming price list | ID: 18781373030

simufact forming

Fully equip yourself with the metal welding & fabrication training needed to start your career in welding, or further your skills. Learn the trade through a variety of GMAW / MIG welding, SMAW / Stick welding, GTAW / TIG welding workshops, courses & more!

sheet metal simulation software|stamping simulation