all pull boxes junction boxes and fittings must be Answer: Paragraph (b)(3) of §1926.405 applies only to pull and junction boxes installed on systems of more than 600 volts. If none of the conductors within the box were over . Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final shape.

0 · utility box junction and pull

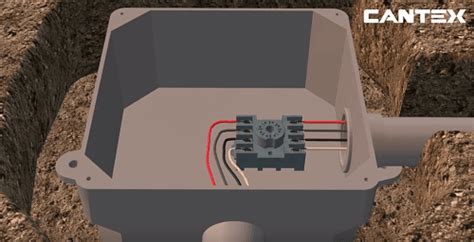

1 · underground electrical pull box installation

2 · standard electrical pull box sizes

3 · nec distance between pull boxes

4 · nec compliant junction boxes

5 · maximum distance between junction boxes

6 · electrical pull box size chart

7 · different types of pull boxes

In sheet metal fabrication, the flange length (or flange height) is the distance between the bend and the part’s edge or the next feature, such as a hole or another bend. If a flange is too short, the sheet metal will slip into the v-shaped die during forming, preventing us from bending the material.

All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box .All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, . Answer: Paragraph (b)(3) of §1926.405 applies only to pull and junction boxes installed on systems of more than 600 volts. If none of the conductors within the box were over .

utility box junction and pull

underground electrical pull box installation

All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box .One acceptable method is a ground fault circuit interrupter (GFCI). Since conductors can be damaged if they rub against the sharp edges of cabinets, boxes, or fittings, they must be . All pull boxes, junction boxes, and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations .

All pull boxes, junction boxes, and fittings must have covers. Metal covers need to be grounded. In energized installations, each outlet box needs to have a cover, faceplate, or fixture canopy.

All pull boxes, junction boxes, and fittings must have covers. Metal covers need to be grounded. In energized installations, each outlet box needs to have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

connect cat5 cable to my telephone junction box

standard electrical pull box sizes

connecting 4 wires in a junction box

All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy. Answer: Paragraph (b)(3) of §1926.405 applies only to pull and junction boxes installed on systems of more than 600 volts. If none of the conductors within the box were over 600 volts, then the requirement in question does not apply.All pull boxes, junction boxes and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations, each outlet box must have a cover, faceplate or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

One acceptable method is a ground fault circuit interrupter (GFCI). Since conductors can be damaged if they rub against the sharp edges of cabinets, boxes, or fittings, they must be protected from damage where they enter. To protect the conductors, some type of clamp or rubber. grommet must be used.

All pull boxes, junction boxes, and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations each outlet box must have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings must have covers. Metal covers need to be grounded. In energized installations, each outlet box needs to have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings must have covers. Metal covers need to be grounded. In energized installations, each outlet box needs to have a cover, faceplate, or fixture canopy.

All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy.

nec distance between pull boxes

Answer: Paragraph (b)(3) of §1926.405 applies only to pull and junction boxes installed on systems of more than 600 volts. If none of the conductors within the box were over 600 volts, then the requirement in question does not apply.

All pull boxes, junction boxes and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations, each outlet box must have a cover, faceplate or fixture canopy.

All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

One acceptable method is a ground fault circuit interrupter (GFCI). Since conductors can be damaged if they rub against the sharp edges of cabinets, boxes, or fittings, they must be protected from damage where they enter. To protect the conductors, some type of clamp or rubber. grommet must be used. All pull boxes, junction boxes, and fittings must be provided with covers approved for the purpose. If metal covers are used they must be grounded. In completed installations each outlet box must have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings must have covers. Metal covers need to be grounded. In energized installations, each outlet box needs to have a cover, faceplate, or fixture canopy.

construction worker metal lunch box

In this article, I’ll be focusing on pancake boxes, otherwise referred to as pan boxes. I explain what building codes say about fan-rated junction boxes, the requirements for a box to be regarded as fan-rated, and whether pancake .

all pull boxes junction boxes and fittings must be|standard electrical pull box sizes