types of cnc part programming Understand the basics of CNC programming with our step-by-step guide. Gain a solid foundation in CNC programming principles and techniques. Learn how to analyze part diagrams and calculate tool paths. Discover the . Standard metal roofing materials include copper, aluminum, steel, zinc, and tin, which come in varying shapes and sizes (slate, corrugated, tile). Metal roofing can last for decades, with many well-made metal roofs lasting .

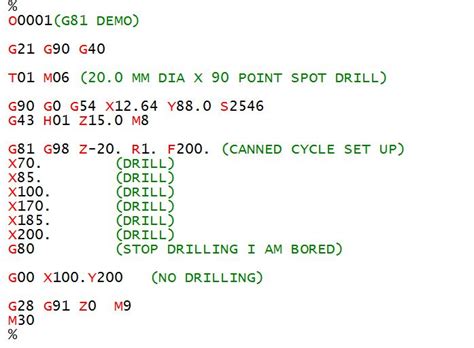

0 · sample cnc program

1 · manual cnc programming for beginners

2 · free cnc program examples

3 · cnc programming for dummies

4 · cnc programming examples with drawing

5 · cnc mill program example

6 · cnc lathe programming for beginners

7 · beginner level cnc programs examples

Description of NEMA electrical enclosures types. Enclosures constructed for indoor use to provide a degree of protection to personnel against incidental contact with the enclosed equipment and to provide a degree of protection against falling dirt.

What are the types of CNC programming software: CNC programming software includes CAD (computer-aided design), CAM (computer-aided manufacturing), simulation, . G-Code. The most fundamental language you’ll encounter in CNC programming. The “G” in G-code stands for “geometric” because this code dictates the actual movements of .

Understand the basics of CNC programming with our step-by-step guide. Gain a solid foundation in CNC programming principles and techniques. Learn how to analyze part diagrams and calculate tool paths. Discover the .

metal dovetail box

There are three main types of CNC programming: Manual Programming, Computer-Aided Manufacturing (CAM) Programming, and Conversational Programming. . Types of CNC Processes. CNC programming encompasses various machining processes that you can use for your business. Here are the different types of CNC processes you need to know about: CNC Routing Types of CNC Programming. When it comes to CNC programming, there are different methods available, each with its own advantages and suitability for specific applications. Here, we will explore three main types . 1. Manual CNC Programming . Manual CNC programming is a time-consuming and inefficient method that requires the programmer to anticipate the program's output while being aware of the machine's .

MANUAL PART PROGRAMMING TyPES OF MANUAL PROGRAMMING: POINT TO POINT, CONTOURING, 3-D. (3-D programming, only with the help of a computer) . WRITE THE PART PROGRAM IN A STANDARD FORMAT SPECIAL MANUSCRIPT AND FLEXO WRITER – TAPE, LISTING etc. (Nowadays, these are is not required) MOSTLY POINT TO POINT programming .

sample cnc program

Numbers the lines of code in a program for organization and easy reference to specific parts. In modern CNC programming, N codes are usually optional but enhance readability and management. . and different types of CNC programming—such as manual, computer-aided manufacturing (CAM), and conversational programming—individuals entering the .Study with Quizlet and memorize flashcards containing terms like What two types of manufacturing processes can a hybrid CNC perform?, What type of CNC machine brings tools into contact with a rotating workpiece?, What component .

CNC (Computerized Numerical Control) machining is a technology that allows machines to perform precise cutting, engraving, drilling, or milling operations based on preset instructions, m-code is a component of the CNC programming language used to control various functions during the machining process. This article provides a comprehensive understanding . 6. Part programming 1. Part programming consists of a sequence of instructions to be performed on the NC/CNC machine. 2. This are two types 1.Manual part programming. 2.Computer – aided part programming. CNC 3. In order to prepare part programming the programmer decides the order of the machining operations required to produce a component. .

CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such as cutting, milling, and drilling. CNC programming involves writing a series of commands, typically in the form of a .

controlling the part programming, and • description of some common miscellaneous or M codes that are used in most of the CNC machine tools. 4.2 PART PROGRAMMING FUNDAMENTALS As discussed earlier, the numerical control machine tools require a part program to generate the requisite geometric shape of the components. The part program is basically a Types of CNC Part Programming. The manual option is one of the types of CNC part programming that involves directly inputting commands into a control console using the G-code programming language, offering complete control over part programs. It’s ideal for ultra-high volume work and demanding applications, demanding deep expertise in CNC .

TYPES OF CNC MACHINE 6. HOW CNC WORKS? 7. FEATURES OF CNC MACHINES 8. CNC PROGRAMMING BASICS 9. COMMON FORMAT OF A BLOCK 10. PROGRAMMING KEY LETTERS 11. ADVANTAGES 12. CHALLENGES 13. . • When running, a part program is interpreted one command line at a time until all lines are completed. • .

The first step in CNC programming is to design the part using CAD software. This involves creating a 3D model of the part, specifying its dimensions, and incorporating any necessary features or details. . type, and material compatibility are considered. 3. Writing the program: The CNC program is written using a programming language such as G . Part programming for nc machines - Download as a PDF or view online for free . • The collection of all instructions (or program of instruction) necessary to machine a part is called an NC program, CNC program, or a part program. • The person who prepares this program is called a part programmer. . which is also used to type the program . What Are the Different Types of CNC Programming? Three main types of CNC programming exist – manual, computer-aided manufacturing (CAM) and conversational. Each has unique pros and cons. Beginner CNC programmers should learn what distinguishes each type of programming from the others and why all three methods are essential to know.

CNC programming is the process of creating and running a program consisting of G code in a CNC machine to move the machine and control its functions. There are a large range of CNC machine types available, from . CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write .

metal ducts vs fabric ducts

CNC programming can be approached in several ways, each suited to different types of tasks and machinery. Understanding the various types of CNC programming helps in choosing the right method for your specific manufacturing needs. Here’s an overview of the most common types of CNC programming. What Are the Different Types of CNC Programming?1. Manual part programming 2. Computer assisted part programming 3. Manual data input 4. NC programming using CAD/CAM 5. Computer automated part programming In manual part programming, the processing instructions are documented on a form called a part program manuscript. The manuscript is a listing of the positions of the tool relative to the work 4. Part programming 1. Part programming consists of a sequence of instructions to be performed on the NC/CNC machine. 2. This are two types 1.Manual part programming. 2.Computer – aided part programming. CNC 3. In order to prepare part programming the programmer decides the order of the machining operations required to produce a component. . There are two most common types of CNC programming in the market, including manual programming and automatic programming. . and correct it in time until the qualified parts are trial-cut. CNC Programming Software List. The listed items are the best free & part CAD/CAM software that most CNC programmers use frequently for programming. UG.

The ease of use provided by automated machine tools has made it easier than ever to manufacture parts for different uses. CNC programming provides automation, cost savings, excellent machining quality, flexibility, reduced production time, and a host of other benefits to manufacturers. . Types of CNC Processes. CNC programming encompasses . CNC | CNC part program, CNC programming | Introduction of part program | G code | M code #lecture 2In this video you will learn about part program which is u.

manual cnc programming for beginners

free cnc program examples

Why Different Types of CNC Programming Exist. We have different types of CNC machine programming because each one serves a unique function in manufacturing. If you’re working on a simple project, like creating door handles, you’ll use a basic programming method that doesn’t require complex inputs or detailed customization. There are generally three types of CNC programming, and each type has its benefits and uses, making it important for a CNC programmer to have a basic understanding of all three. . CNC programming is an integral part of operating a CNC machine to perform the desired machining operation. One of the significant advantages of CNC milling machines is their ability to machine complex geometries with ease. They utilize computer programming and automated processes to produce intricate designs and shapes, enabling manufacturers to create high-quality parts with exceptional precision.The part program is a sequence of instruction that describe the work that is to be done to a part. . Each type CNC machine will have different name for the operation they perform to parts to achieve the desired geometry on a part such as tasks like drilling, or cutting threads, but perform these actions differently. .

metal doll house vintage

CNC Programming. Flashcards; Learn; Test; Match; Q-Chat; Get a hint. what does CNC stand for? computer numerical control. 1 / 39. . (to form some type of processing) what are the major components of a CNC system? . the part program generates signals to .

cnc programming for dummies

Nassau National Cable offers all kinds of electrical boxes, including junction boxes, standard rectangular boxes, square boxes, octagon boxes, round pan boxes, weatherproof .

types of cnc part programming|cnc mill program example