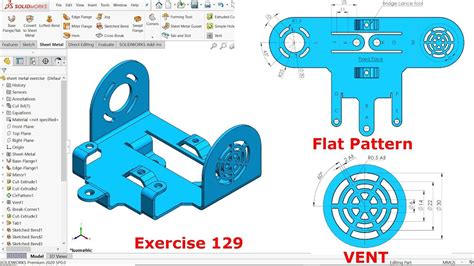

sheet metal diagrams Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental . Environmental profile of Tungsarc Metal Fabricators Co. Tungsarc Metal Fabricators Co is located at 3 9 Hillman St, Paterson NJ, 07522.

0 · solidworks sheet metal drawings

1 · simple sheet metal drawings

2 · sheet metal layout drawings

3 · sheet metal drawing for practice

4 · sheet metal drawing examples

5 · sheet metal bending chart

6 · sheet metal basic drawing

7 · basics of sheet metal design

$18.99

Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental .A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best .Features. SHEET METAL INTRODUCTION. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall . Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, .

Counter sinks – A counter sink can be put in sheet metal by both machining and/or punching. Each of these methods give the finished part different characteristics. The cross sections of . Follow these best practices next time you create a sheet metal fabrication drawing to help your shop turn the project around quickly: 1. List part numbers, not just the part name. Part names are great, but it’s helpful to .

What is Sheet Metal Drawing? Sheet Metal drawing process. Sheet metal drawing is not merely a process but an art, where flat metal sheets transform a three-dimensional shape by getting drawn over a die without . The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Learn about sheet metal here!

coeur d alene metal fabrication

Learn the basics of sheet metal layout including different seams, techniques and tricks. This video also includes the patterns and layout methods for creati.Do you have dents, dings, rust, or other damage to your Mopar's door shells, fenders, hoods, or any other sheet metal? NPD has what you need to restore your piece of American history to its full glory. Industry's Best Quality 1960-1976 Mopar Sheet Metal Parts. Browse the industry's best sourced selection of Mopar sheet metal products right here. Question: Question 2(40%)Figure Q2: A sheet metal produced by a rolling millFigure Q2 illustrates the production record of sheet metal produced by a rolling mill. The sheet has a nominal thickness of 1 mm , with a specification of 1.00+-0.05mm. A quality inspector measures a sample of five sheets at the end of each day. Sheet Metal: Sheet Metal is a thin sheet produced by rolling or hammering. These thin sheets are used to produce various types of sheet metal products by a sheet metal manufacturer according to requirements. The .

The sheet-metal worker's guide : a practical handbook for tinsmiths, coppersmiths, zincworkers, etc., comprising numerous geometrical diagrams and working patterns, with descriptive text Bookreader Item Preview remove-circle Share or Embed This Item. Share to Twitter. Share to Facebook. Share to Reddit. Share to Tumblr. Share to Pinterest . Table of Contents. 1 5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. 1.0.1 1. List part numbers, not just the part name; 1.0.2 2. Use the exact hardware name when possible; 1.0.3 3. Provide details for revision control Sheet metal is a thin piece of metal between 0.006 and 0.25 inches thick. Sheet metal can be cut, bent, and stretched into various shapes through forming and cutting operations. Common forming operations include bending, deep drawing, and roll forming. Common cutting operations include shearing, blanking, punching, notching, and slitting.Sheet metal parts with a minimum of 0.9mm to 20mm in thickness can be manufactured. Hole Diameter. When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Bends. Bends in sheet metal are manufactured using sheet metal brakes. A +/- 1 degree tolerance on all bend angles.

Sheet metal is metal formed by an industrial process into thin, flat pieces. It is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes. Countless everyday objects are constructed with sheet metal. Thicknesses can vary significantly; extremely thin thicknesses are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) .

A forming limit diagram, also known as a forming limit curve, is used in sheet metal forming for predicting forming behavior of sheet metal. [1] [2] The diagram attempts to provide a graphical description of material failure tests, such as a punched dome test.In order to determine whether a given region has failed, a mechanical test is performed. The mechanical test is performed by .

The grouping of diagrams by “section” is similar to how the Ford Motor Company originally organized its Master Parts and Accessories Catalog . Sheet Metal - under body 1967/70 body type 63, 1967/69 body type 65 . 126 . 5467 . Sheet Metal - 76 under body . 127 . 5468 . Sheet Metal - 63 upper body . 128 . Second Generation Camaro Owners Group - Front End Sheet Metal & Hardware. The assemblies we're dealing with in this section are front end sheet metal. Fenders, core supports, inner fenders, hoods, installation hardware (bolts). . Exploded Diagrams of Camaro Front End Sheet metal. 1970 - 1972 Camaro Front End. 1970 - 1972 Rally Sport Camaro .Show Diagrams. CATAGORY 2 Search × clear filters Home › 1966 1967 CHEVELLE BODY SHEET METAL. 1966 1967 CHEVELLE BODY SHEET METAL. 66 67 MALIBU 300 STEEL BODY PANELS Ref# Image. Part (for more info on part click on red part#) Price. Qty #1. TRUNK LID RODS, NEW PAIR 66 67 GTO CHEVELLE SKYLARK. Part #872024 .Metal Forming: Formability. A.G. Atkins, in Encyclopedia of Materials: Science and Technology, 2001 5 Forming Limit Diagrams. In the widest meaning, a forming limit diagram plots important variables, or groups of variables, to show combinations of conditions for which a particular method of forming is possible and those for which it is not possible. In tube bending, failure is either .

In sheet metal, this question always creates some confusion. What is the difference between punching blanking and piercing? Punching blanking and piercing are sheet metal shearing operations to modify existing blank. Similar machines but different punch and die are used to perform these operations.

> Metal Forming > Forming Limit Diagrams; Metal Forming. Mechanics and Metallurgy. Buy print or eBook [Opens in a new window] Book contents. Frontmatter. Contents. . Sheet Metal Properties. Index. References; 16 - . A forming limit diagram (FLD) can be universally applied to the prediction of fracture instability during sheet metal forming under different working conditions. However, with the continued development of diverse, lightweight metal products, the problem of sheet metal wrinkling instability during forming operations has gradually become as .The Forming Limit Diagram is a combination of the Forming Limit Curve (a material property) and the strains (reflecting part geometry and forming conditions). . Creating a subsequent FLD may be warranted when conditions .

Sheet metal forming boundaries are established using the forming limit diagram (FLD). The Nakajima and Marciniak tests, which are based on stretching a material using a punch, are the most commonly used methods for determining the FLD or fracture forming limit diagram (FFLD). The results are usually evaluated by calculating local strain, strain rates, .

John Deere 5093E Sheet Metal and Grille Exploded View parts lookup by model. Complete exploded views of all the major manufacturers. It is EASY and FREE. . See: Ariens exploded parts diagrams. We sell parts & accessories for your Briggs & Stratton equipment.Description: The 1966 Mustang Part & Body Illustrations manual is a comprehensive collection of detailed part and body illustrations that are extremely useful for any restoration project. For example, part illustrations are “exploded” to show not only the parts of a component, but can be used to identify the basic part number of virtually every nut, washer, etc.

64 65 66 67 1964 1965 1966 1967 gto le mans tempest floor quarter fender door rear panel rocker roof firewallVol-2 Issue-2 2017 IJARIIE -ISSN(O) 2395 4396 C-1496 www.ijariie.com 155 Forming Limit Diagram for Sheet Metal Forming: Review Sekhara Reddy A C1 T.Pavan Kumar2 1Professor, Sreyas Institute of Engineering and Technology, Hyderabad, India. 2HOD, Department of Mechanical Engineering, NNRG, Hyderabad, India Abstract The accurate description of . 11 - Chassis Sheet Metal 1970 - 73 Std. Front End 1970 - 73 RS Front End 11A - Front Fenders (exploded) 11D - Hood 11E - Misc Frt End Sheet Metal 11G - Ornamentation 11Z - Misc Info 12 - Electrical - Chassis & Body . Wiring diagrams, emissions & tuneup specs are from GM Shop manuals.

Forming limit diagrams (FLD) have been widely used to predict the formability in sheet metal forming processes since FLDs were proposed by Keeler and Backofen, 1963, Goodwin, 1968.FLDs can be constructed by experiments such as hemispherical punch-stretch tests and Marciniak cup tests (Marciniak et al., 1973).These experimental methods, however, .

The Sheet-metal Worker's Guide: a Practical Handbook for Tinsmiths, Coppersmiths, Zincworkers, Etc., Comprising Numerous Geometrical Diagrams and Working Patterns, With Descriptive Text [Crane, W J E (W J Eden)] on Amazon.com. *FREE* shipping on qualifying offers. The Sheet-metal Worker's Guide: a Practical Handbook for Tinsmiths, .

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download!

In this article, you’ll learn the various types of sheet metal operations with their diagrams. Types of sheet metal operations The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Shearing Operations. The Shearing operation is a cut in a .

solidworks sheet metal drawings

Prewash fabric before painting to remove sizing and do not use fabric softener. Top selling color combined in one pack. Perfect for outfits, multiple projects and group activities.

sheet metal diagrams|basics of sheet metal design