how to reset cnc machine Try looking for a red reset button on the control panel (not the OMi panel) The bridgeports I'm used which are earlier models than yours had it. You put the machine in zero . Used Office File Cabinets. Our used filing cabinets come in a wide array of styles, colors, and sizes. Whether you’re looking for smaller desk storage or a larger set of filing drawers, our inventory has what you need. Looking for mobile or .

0 · power up restart cnc machine

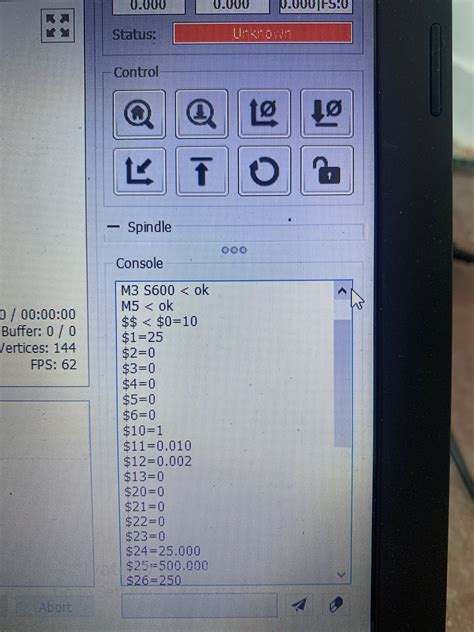

1 · lightburn cnc3018 reset

2 · lightburn cnc 3018 restore

3 · how to restart cnc machine

4 · how to power up cnc machine

Search for used mini cnc milling machines. Find Acer, Sharp, Haas, Benchman, Doosan, Fadal, Antishicnc, Gooda, Leeder, Huron, and Wadjay for sale on Machinio.

Chris and Rick cover Reset, including what it does and best times to use it (or not to)! Subscribe for more CNC training, autopsies, dinosaurs, science videos and general geek related awesomeness. My CNC 3018 start moving opposite direction. I hope there is a way to restore the default configuration comes with the machine.

In this video the CNC Repairman goes through how to power up restart a CNC machine and trouble shoot power on issues. One of the most common issues on a Tormach is for the machine to get stuck in a reset condition. Jason describes the different solutions to this issue, and d. Try looking for a red reset button on the control panel (not the OMi panel) The bridgeports I'm used which are earlier models than yours had it. You put the machine in zero .

Double check the owner’s manual for your CNC router to make sure this procedure is correct for your machine. Watch this video to see stopping and restarting in action. We’ll need the following buttons to stop and restart . Here’s how to perform a configuration reset. (machine not working correctly, machine cutting shrunk or stretched, ipp rail upgrade sizes) Please note, resetting the configuration will change any custom values you have . How to Fix: The only and the best way to resolve this issue is to ensure that machine operators follow a regular maintenance and clean-up routine for their CNC machines. Besides cleaning dirt and dust, machine operators .

When the machine first powers up, the first screen you get is the MESSAGE screen telling you that the bar feed is in alarm. So, you go initialize the bar feed and then go back to .I have a home built CNC Router controlled by a DDCS V3.1 controller. I moved it around once I got the steppers working and now it’s time to test it but the machine coordinates need to be reset. I can’t find online anything about how to do that. We look at some of my tips for setting the Z zero or the Z height before starting a job on your CNC machine. I start by covering the basics before moving ont.

BobsCNC is what happens when two old friends, one with a background in mechanical engineering and a long history of building CNC machines and the other with a career in sales and marketing, join forces along with their wives and family.

power up restart cnc machine

Push [EMERGENCY STOP]. Note: User Data and Memory will be erased before a restore if the backup includes User Data and Programs. Push [ENTER] to select and deselect what you must restore.. Push [F4] to restore the machine. Note: Alarms after the machine restore are normal.Continue the procedure. Power off and power on the machine. Set Setting 155, .Vertical Mills ; VF Series; Universal Machines; VR Series; VP-5 Prismatic; Pallet-Changing VMCs; Mini Mills; Mold Machines; High-Speed Drill Centers; Drill/ Tap/ Mill Series Gorilla CNC Machines; K2CNC; Larken; Multicam Machines; Omni CNC; Roctech CNC Routers; Shopsabre; Stepcraft; Techno CNC; XYZ Gantry Routers; DIY CNC Router Table Machines. FAQ of DIY CNC Machine Building; Avid CNC; CNC Wood Router Project Log; FineLine Automation; Joes CNC Model 2006; Momus Design CNC plans; Open Source CNC . Sign up for the free WWGOA newsletter to receive the latest videos, articles, and tips straight from the experts! 🔨 https://bit.ly/3H3BzvC There are times w.

Callipers for testing - https://amzn.to/3sl7Cl3Dial indicator and stand - https://amzn.to/3IpOOXjPainters tape - https://amzn.to/3JVNYSISainsmart 3020 Pro Ma.I'm new to CNC machines and have an issue. I have an entry level FoxAlien machine with a 20w laser module. . If you don’t have actual switches, you can use a gcode command to reset the controller’s understanding of the tool’s current position. G92 X0 Y0 Z0 says “the current tool position is now 0,0,0” Reply reply

Every now and then you may find that you need to readjust the chains back to a known position. This could occur if you power/connection issue and the controller lost it’s position, had a chain skip, took apart something for some reason, etc. Fortunately, there’s a way to reset the chains without a lot of work. During calibration, after you set the sprockets vertical, you .

In this video we look at how to correctly home our OX-Metal CNC mill, As well as cover how to correctly home the work piece. Art Pics kindly provided for fre.Hello friends, Welcome to our YouTube channel HPDC & CNC SOLUTIONAbout In this video how do we reset the parts counter and runtime of no fanuc. Hi Denvi, a. When you press the 'Restore X, Y, Z' button only X and Y are restored. Z should move too. b. Pressing 'Zero XY' and 'Zero Z' works OK to offset from Machine co-ords. But if you then press 'Reset' to reset the Arduino the cur.Zero Return parameter setting procedure for Fanuc 16/18 and 16i/18i Controls . Move the axis to where you think zero return should be. If you can't get to the position you would like, hold in "P" and "Cancel" on power up to bypass soft overtravels or you could change the soft overtravel limits to .

Axiom CNC Training & Tech Tips (How to home your CNC) In this video we will cover how to complete the home operation on your Axiom CNC. Tech Tips: 00:20 Reme.I ended up getting a call back from the Laguna CNC Company. They are amazing. The problem was that the pulse settings on the machine were set to 400 in x,y, and z. They should be set to 320. The tech at Laguna was super helpful. He sent me the new file to reset the handheld controller. I’m good to go now! About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright . Yea; what he said. This is what I might have tried if simply clicking on the reset icon didn't work. If it doesn't work you can still get to the screws that hold the limit switch in place. Just mark its position, remove it completely, shut off the machine and restart.

My Machine stopped in the middle of my G-Code! PC to Control Panel Connections. USB Connectivity , no connection to the CNC; Reset NCPod - No Connection to Controller; Reset your machine to X=0, Y=0. Though it sounds simple, it turns out to be an interesting challenge to accurately put the center of your bit or mill over that edge.

I have a Mighty Viper VMC-950AG with a Magic 64 control. The other day the machine over traveled in the Y positive. I can not get the machine out of over travel. I have the way covers off, but I obviously can't turn the ball screw by hand. I tried one of the rubber oil filter strap wrenches, again no luck. Machine gave a change battery alarm (changed them) but apparently not in time. Found a thread here that showed how to reset the tool changer so it knew which tool was in the spindle but the spindle index is off by a degree or two and the tools try to sit on the lugs instead of having the lugs in the tool holder grooves. I am working on a wire bending machine. I am trying to find a way to reset the machine coordinates to home after each part. The wire that I am bending has perforations. What I would like to do is have a block of code at the beginning of the program that would run the X axis homing sequence. This would work in conjunction with a photo eye to . benjamint76 suggested that to Zero the Machine Coordinates, you click the Machine Coordinates box so that it turns red, move the spindle to home and then start clicking Zeros. He said that once done, you click Machine Coordinates again and you will be back in .

Double check the owner’s manual for your CNC router to make sure this procedure is correct for your machine. Watch this video to see stopping and restarting in action. We’ll need the following buttons to stop and restart your machine: Stop, Arrow up .I have a usb cnc driver board on your 1'x3' cnc and i cant get the z+ limit switch to stop the machine in the provided software. It registers the button but doesn't inhibit movement. inversly the button works when selected as '-' for negative movement.

For anything CNC related: CAD, CAM, automation, and more! . No2005 Magazine counter missing How do i reset tool magazine? Share Add a Comment. Sort by: Best. Open comment sort options. Best. Top. New. Controversial. Old. Q&A. . Theres a page in the setting where it shows what pot number and tool the machine thinks it has. We just got to .

lightburn cnc3018 reset

Get the best deals on Metal Home Storage Boxes when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

how to reset cnc machine|lightburn cnc 3018 restore