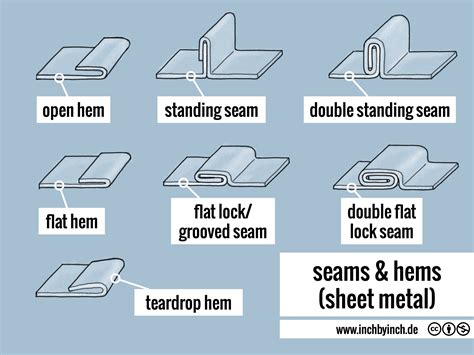

single seam joint in sheet metal Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials. 1. Hemming Straight Hem.(Image source) (Image source) Contour hemming.(Image source) Hem detail.(Image source) Types of Hemming.(Image . From simple two-pin connectors to complex multi-pin connectors, the chart delineates the characteristics of each connector type, allowing designers to select the most suitable option for their specific requirements.

0 · what is a sheet metal joint

1 · types of sheet metal seams

2 · types of seam joints

3 · sheet metal side seam

4 · sheet metal seams pdf

5 · sheet metal seams explained

6 · sheet metal seam joints

7 · sheet metal corner joints

There are six major types of sheet metal material, each with its own unique advantages: 1. Aluminum. For applications that require a more lightweight material, aluminum is an excellent option. This type of sheet metal offers significant corrosion resistance even without a finish.

what is a sheet metal joint

metal manufacturing precision component

types of sheet metal seams

The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used methods for joining light- and medium-gauge sheet metal. It consists of two folded edges that are locked together with a .The Basic Lap Joint . A variation of the lap joint is the . nested. lap, which is utilized by many types of ribbed metal panels. A nested lap joint overlaps the adjacent panel, but also covers or "nests" the lower panel rib within the rib of the lapping panel. This is the seam joint shown in Figure 15-2. Figure 15-2 The Nested Lap Joint When hemming is carried out in a way that a joint between two sheet metal parts is created, it is called seaming but more on that later. . A seam is used to connect two metal parts by interlocking the edges of the folded .

26 Sheet metal joints • Hems & seams – • A hem is an edge or border made by folding • It stiffens the sheet of metal and does away with the sharp edge • seam is a joint made by fastening two edges together • Types of .Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials. 1. Hemming Straight Hem.(Image source) (Image source) Contour hemming.(Image source) Hem detail.(Image source) Types of Hemming.(Image . Sheet metal joints are found in every sheet metal assembly. Sheet metal fabrication techniques create these special joints to enable the proper function of t.

Joints. The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used methods for joining light- and medium-gauge sheet metal. It consists of two folded edges that are locked together with a HAND GROOVER (fig. 2-58). When making a grooved seam on a cylinder, you fit the piece over a stake and lock it with the hand groover (fig. 2-59). This joint is used for locking seam joints in sheet metal work. Fig. 1.11 Various sheet metal joints 4. Hem (single and double), wired edge, cup and angular joints. These enable the edges sheet metal part to join the pieces along them. 5. Flanged joint. It is commonly used in sheet metal work frequently in making pipe connections. 6. Cap joint .

metal lunch box plate

Joints The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used methods for joining light- and medium-gauge sheet metal. It consists of two folded edges that are locked together with a HAND GROOVER (fig. 2-58). When making a grooved seam on a cylinder, you fit the piece over a stake and lock it with the hand groover (fig. 2-59).Seam Joint A seam is a joint made by fastening two edges to each other. Hem Joint Hem is an edge or border made by folding. It stiffens the sheet and does away with the sharp edge. Generally, two types of Hem joint – single hem and double hem – are there. Single Hem joints are made by folding theA variety of seams are used to connect pieces of sheet metal in construction, auto body creation and fine art sculpture. The type of seam used depends largely on the application; some seams are created entirely by machine or in a metal shop, while others are made to snap together without requiring welding or soldering on site. Then the metal goes through the roll former, which creates the joint end of the sheet metal duct, . For smaller ducts it might be possible to make the duct section out of a single piece. The seam gets knocked together either as a snap lock .

#sheet metal #sheet #sheet metal operations #types of sheet metal joints This video is about sheet metal joints and types.hem and types, seam and types.इस वी.Tutorial: Chimney Cladding – Standing Seam Tutorial: Lateral window abutments – Part 1 Tutorial: Angle standing seam facade, horizontally oriented – cross jointStudy with Quizlet and memorize flashcards containing terms like 1. Shearing 2. Blanking 3. Punching 4. Bending 5. Hemming 6. Hallowing 7. Folding 8. Swaging, > single hemming > double hemming, 1. Seam Joint 2. Lap Joint 3. Standing Seam Joint 4. Grooved Seam Joint 5. Corner Joints 6. Double Corner Seam Joint 7. Pittsburgh Lock Seam 8. Soldering 9. Riveting and more.

According to the requirements many different types of joints are used in sheet metal work. A lap joint is very frequently used and can be prepared by means of soldering or riveting. Seam joint is a very commonly used one. It .

A single joint can be welded using various weld types, depending on the design and strength requirements. . Seam weld; Lap joints are often used in sheet metal applications, such as ductwork, frames, and other structures. .

Study with Quizlet and memorize flashcards containing terms like On a sheet metal fitting layout with a single bend, allow for stretching by, Rivet pitch is the distance between the, Under certain conditions, type A rivets are not used because of their and more. . the shear strength of the riveted joint. A rivet set used to drive MS20470 .

Sheet metal, metal roofing and standing seam seaming tools for industry professionals. Quality Tools. . Seam Opening Pliers. Lap-on joint, precoated handles. Jaw width 1 1/8" 0.99lb length 9 7/8" . ESE 001-625 First Stage Hand Seamer. For single locking the 5/8" (0.625") wide standing seamSingle lock hand seamerForms the 90 degree bendFor .

Learn how sheet metal joints are made and used in the HVAC sheet metal industry to make air conditioning ductwork. . Vertical Duct Seam Closing Machine S & Drive Joint. . and Mid Panel Tie Rod Distance (#4) will effect the Maximum Duct Width (#3) that can use a single toe rod for reinforcement when using a Mid Panel Tie Rod distance of 2-1/ .As we mentioned above, sheet metal hemming is a process of folding the edge of a single metal sheet back onto itself to create a clean, finished edge. This is typically done by bending the metal over a die or roller, resulting in a 180-degree fold or a tighter, more acute angle. . The seam is created through a specific pattern of bends, such .sketch the various types of sheet metal joint, . It is used for folding and bending the side edges of the metallic sheet blank to form the joint at the seam. Normally, it is used for shaping metal sheet into cylindrical shape. . single hem and double hem – are there. Single Hem joints are made by folding the edges of the sheet over once .- Review of Types of sheet metal Fabrication. - Methods of developments. 2 - Locked groove joint by aluminum sheet - Single riveted lap joint by aluminum sheet. - Double strap single row riveted butt joint by aluminum sheet - Introduction to Aluminum fabrication, and its applications. - Ferrous and Non-Ferrous metals. Use of Copper and Alloys.

The butt joint with a single cover plate is a rivet joint that involves placing two metal sheets edge-to-edge and using a single cover plate, which is riveted over the seam. It provides additional strength and rigidity, reduces stress concentration, and has an aesthetically cleaner look compared to lap joints.

These joints are common in sheet metal fabrication, pipelines, and structural applications. . These types of joints are among the most common in the sheet metal industry, found in the construction of frames, boxes, and other applications. . Two pieces of metal are placed edge-to-edge and welded along the seam to create a single, larger piece.The PAC-CLAD PAC-150 90° single lock standing seam metal roofing panel system offers an attractive thin-rib profile with a 1.5" leg height. Products. . content_paste Spec Sheet. Features. task_alt 35-year non-prorated finish . PAC-150 standing seam metal roofing panels combine semi-structural metal panel performance with architectural .The first and most obvious is the spiral seam. It is the only duct seam short of a full weld that does not require sealing according to ASHRAE 90.1. The second advantage is that the perimeter of round and flat oval duct is less than rectangular so each joint that must be sealed is smaller. Third, there are fewer of these smaller joints.

Seam Joint In Sheet Metal Canada. Patent Office. Content Interpretation of Metal Fab Drawings Cameren Moran,2021 . covers two similar fundamental processes—foundry and welding—in a single volume. The chapters of the book are grouped in seven modules. A separate module is devoted to introduce the preliminaries of the two areas namely .

Old work boxes are designed to be installed in finished walls, have tabs or clamps that grip the drywall from behind, and are available in both plastic and metal. The most common old work box has tabs that pop out when pushed into the wall, securing the box to the drywall.

single seam joint in sheet metal|what is a sheet metal joint