cnc part programming for turning operation 6. Part programming 1. Part programming consists of a sequence of instructions to be performed on the NC/CNC machine. 2. This are two types 1.Manual part programming. 2.Computer – aided part programming. CNC 3. In order to prepare part programming the programmer decides the order of the machining operations required to produce a component. .

Vintage Blue/Green WATERLOO Metal Hand Tool Box with Tray 19”x 7 1/2"x 7 1/2" E

0 · sample cnc program for turning

1 · cnc turning programming with graphics

2 · cnc turning programming pdf

3 · cnc turning programming examples pdf

4 · cnc turning programming examples

5 · cnc turning cycle program pdf

6 · cnc programming examples with drawing

7 · cnc lathe programming for beginners

Find waterproof junction boxes, outdoor sockets, electrical connectors and extension lead boxes at Toolstation. Browse products from leading brands with different IP ratings for weather protection.

sample cnc program for turning

old white sewing machine metal black box of accessories

cnc turning programming with graphics

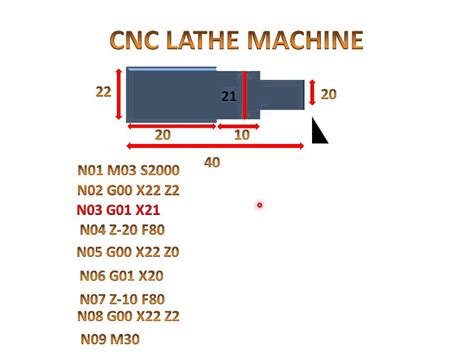

CNC Programming for Turning. For More Details Click here. Learn CNC Machine operation & Maintenance. Visit here. Facing program; Taper turning; GroovingIn this comprehensive guide, we have explored CNC turning programming, providing step-by-step examples for machining a simple shaft and creating internal threads. By mastering CNC . #cncturningprogram #basiccncprogramming #cncprogramforbeginners #cnc #excellentideasineducation #cnclathe #cncprogramming #mechanicalengineering #mechanical .

This is the ppt of CNC turning with Fanuc system.It helps you to encourage your CNC programming skills,also in this ppt some theory of CNC turning are available which helps you to do the programming in the proper .There are different programming languages used for CNC turning, such as G-code and M-code. In this chapter, we will provide an overview of these languages and explain how they are used to program CNC turning operations. Chapter 5: CNC Turning Part Programming Steps\ This chapter will walk you through the step-by-step process of programming a . 6. Part programming 1. Part programming consists of a sequence of instructions to be performed on the NC/CNC machine. 2. This are two types 1.Manual part programming. 2.Computer – aided part programming. CNC 3. In order to prepare part programming the programmer decides the order of the machining operations required to produce a component. .

CNC Turning Program For Beginners With SimulationLet's find out in this video..CNC Step Turning Program with Simulation!Now learn with fun, say goodbye to .Taper turning is a machining operation that involves gradually reducing the diameter of a cylindrical workpiece at a certain angle. . results in terms of taper accuracy, surface finish, and overall part quality. So, go ahead and master the art of CNC part programming for taper turning and unlock new possibilities in your machining projects. .

old time metal outet box

[Hindi] Step Turning program for CNC | CNC Machine Co ordinate CNC Tool movement | CNC Step TurningIn this video i explain the working of CNC Tool and the st. CNC Drilling [Hindi] | Drilling Operation on CNC Machine, Part Program for CNC Drilling CNC MillingIn this video you will learn about CNC Milling operation a.G02 G03 Circular interpolation CNC mill example program. G02 G03 Example CNC Mill CNC Part Program G0 X30 Y-30 (P1) G1 Y22.67 (P2) G3 X24.07 Y26.18 R4 (P3) G2 X-18.27.MANUAL PART PROGRAMMING TyPES OF MANUAL PROGRAMMING: POINT TO POINT, CONTOURING, 3-D. (3-D programming, only with the help of a computer) . WRITE THE PART PROGRAM IN A STANDARD FORMAT SPECIAL MANUSCRIPT AND FLEXO WRITER – TAPE, LISTING etc. (Nowadays, these are is not required) MOSTLY POINT TO POINT programming .

Section 1: Understanding the Basics of CNC Turning . Explain what CNC turning is and its importance in the manufacturing industry. Discuss the components and tools used in CNC turning. Highlight the benefits of using CNC machines for turning operations. Section 2: Designing the Part . Describe the importance of designing the part before writing .Palmetto Training, Inc. is accepting new students for our CNC program. The course is 16 weeks long, 500 hours. . and a 4 week (operation program) Part I: Basic Mathematics. Fractions: Add, Subtract, Multiply, & Divide; Decimals: Add, Subtract, Multiply, & Divide; Part II: Blueprint Reading. . Advanced Part Programming; Location Times Date . CNC programming for beginners can be simplified into six key steps: familiarize yourself with the machine and its capabilities, create or obtain a detailed 3D model of the part, generate the toolpath using CAM software, write the G-code program, set up the CNC machine with the appropriate tools and workpiece, and run the program while monitoring for any issues.

Part Zero on CNC Turning Programs. It’s worth putting a little thought into where you’d like to put part zero on a turning program. The X-axis zero is always chosen to be the spindle center line when turning for all sorts of reasons. For the Z-axis zero, there are three popular spots to choose from:

Before running a CNC program the operator should _____. - Execute the toolpath block - Home the axes - Check coolant level - Remove the tool from the spindle - CNC part program

The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions. Advantages of CNC .

Steps to write a CNC program : https://youtu.be/eL4XIA4r_UAMiscellaneous function (M code) : https://youtu.be/6I25EiWXgjcPreparatory function (G code) : http.

Fanuc CNC Programming for Turning . Now that you understand the basics of Fanuc CNC programming and have your machine set up, let's take a closer look at the programming process for turning operations. Creating a Roughing Pass . .CAMWorks 2 and 4 Axis Turning software for programming CNC lathe machines includes automatic roughing, finishing, grooving, threading, cutoff and single point cycles. . rough OD/ID turning and facing operations. . Complex parts can be machined in one setup by using the B axis cutting capability, which helps avoid the need to reconfigure the .CNC turning is a technology that automates turning operations by controlling machine equipment using digital programming. CNC turning achieves automated processing with the use of CNC machine tools and computer technology, which can significantly increase output and quality. A large variety of items, such as shafts, sleeves, disc covers, cams . Subject - CAD/CAM/CAEVideo Name - Part Program on CNC Turning-IChapter - Design to Manufacturing Faculty - Prof. Sushant PatilUpskill and get Placements with.

CNC (Computer Numerical Control) programming plays a crucial role in modern manufacturing processes. Among the various operations in CNC machining, turning cycle is a widely used technique. In this blog post, we will delve into the world of multiple turning cycles and discuss how they can be implemented in CNC programming.

In this blog post, we will explore the process of creating a relevant CNC part program for step turning, a common machining operation. Step 1: Understanding Step Turning . Step turning is a machining operation used to create cylindrical components with different diameters along the length of the workpiece. It involves a series of incremental . CNC KNOWLEDGE is definitely the CNC Machinist Online Resources. You are warmly welcome to the world of CNC (Computer Numerical Control). CNC KNOWLEDGE provides free and detailed articles about cnc programming and machining etc. Easy to understand cnc programming examples are described with detail and images.CNC KNOWLEDGE is for . The CNC Turning Center is one of the critical devices in today’s machining environment, as it allows the manufacture of complex parts with high levels of accuracy and productivity. This document addresses the parameters for mastering the CNC Turning Center, providing a consistent framework for machinists and engineers to develop their skills using .

Fanuc G81 drilling cycle is used for simple drilling operations, so here is a cnc program example which demonstrates how G81 drilling cycle can be used. CN. . N9- CNC part-program is ended. G & M Codes. Code Description; T: Tool no. used. M06: . CNC Lathe Programming Exercise Fanuc G71 Turning Cycle, G74 Peck Drilling Cycle . This information will be included in setup documentation. Doing this before programming may expose an issue that affects what the program must do. Step 6: Write the documentation. Develop setup and production run documentation as if the CNC program has already been created.

Our stainless steel waterproof junction boxes can be used with our outdoor cables to create an IP 68 dust, waterproof, and fully submersible enclosure for your wire splices. Junction boxes are available in two port, four port, six port, and ten port.

cnc part programming for turning operation|cnc lathe programming for beginners