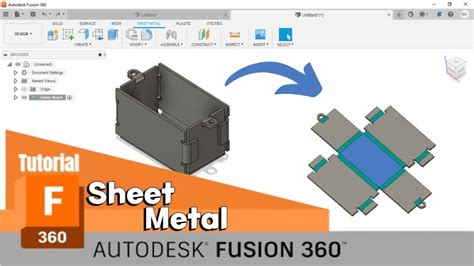

autodesk fusion sheet metal Learn the foundational concepts of the Sheet Metal workspace in Fusion. See .

Open the junction box to expose the terminals. Place the positive lead on one terminal and the negative lead on the other. Measure the voltage. If the voltage displayed is a negative number, then it means the polarities between the .

0 · sheet metal fusion tutorial

1 · sheet metal fusion autocad

2 · sheet metal design fusion 360

3 · fusion 360 sheet metal tutorial

4 · fusion 360 sheet metal cad

5 · autocad sheet metal design

6 · Autodesk sheet metal software

7 · Autodesk Fusion 360

This size drill bit should be used for drilling the initial hole that will then .

The Fusion Sheet Metal skill path gives you the fundamentals for working with sheet metal. Learn to create flat patterns from 3D models, work with all sorts of bends, customize your materials, .

In Fusion, a sheet metal part starts out as a flat piece of metal with a consistent .Sheet metal manufacturing. Learn how to create a sheet metal drawing with a .

Learn how to use rules to define materials and sheet metal features. Edit existing .In this post, we will take a deep dive into why you need to start using the sheet .

Learn the foundational concepts of the Sheet Metal workspace in Fusion. See . In this post, we will take a deep dive into why you need to start using the sheet metal functionality inside Fusion 360. Whether you have been bending sheet metal since the invention of the press brake or you just created .Autodesk Fusion streamlines the deformation-based sheet metal forming process. The software simplifies simulating sheet metal forming with easy setup of loading conditions, contact .Sheet metal design is the process of engineering sheet metal into equipment, parts, assemblies, and products. Autodesk Fusion 360 provides the necessary software to automate sheet metal .

Learn the foundational concepts of the Sheet Metal workspace in Fusion. See how to create a sheet metal component, use rules to redefine the sheet metal part, and take it to drawings or .

Autodesk Fusion delivers a modern, cloud-connected CAD/CAM solution that helps fabricators, prototypers and engineers streamline the production of wood, metal, plastics, and composite parts. Download free trialIn Fusion, a sheet metal part starts out as a flat piece of metal with a consistent thickness. A flange feature consists of a face and bend connected to an existing face along an edge. In the .The Fusion Sheet Metal skill path gives you the fundamentals for working with sheet metal. Learn to create flat patterns from 3D models, work with all sorts of bends, customize your materials, .

Create a sheet metal component using Fusion.

Learn about the importance and role of Sheet Metal Rules. Learn how to apply the Flange command to make faces, flanges, and contour flanges. Discover why a sheet metal part may not generate a flat pattern. Learn how to document .The Fusion Sheet Metal skill path gives you the fundamentals for working with sheet metal. Learn to create flat patterns from 3D models, work with all sorts of bends, customize your materials, and practice the principles of manufacturing and begin applying your new skills to real-world projects. In this post, we will take a deep dive into why you need to start using the sheet metal functionality inside Fusion 360. Whether you have been bending sheet metal since the invention of the press brake or you just created your first flange, one flange command will improve your design process.Autodesk Fusion streamlines the deformation-based sheet metal forming process. The software simplifies simulating sheet metal forming with easy setup of loading conditions, contact conditions, fixes and displacement boundary conditions, and non-linear material properties.

Sheet metal design is the process of engineering sheet metal into equipment, parts, assemblies, and products. Autodesk Fusion 360 provides the necessary software to automate sheet metal design (US Site), nest your components, and create tool paths for CNC.Learn the foundational concepts of the Sheet Metal workspace in Fusion. See how to create a sheet metal component, use rules to redefine the sheet metal part, and take it to drawings or CAM for manufacturing.Autodesk Fusion delivers a modern, cloud-connected CAD/CAM solution that helps fabricators, prototypers and engineers streamline the production of wood, metal, plastics, and composite parts. Download free trial

cnc machine for woodwork covington la

In Fusion, a sheet metal part starts out as a flat piece of metal with a consistent thickness. A flange feature consists of a face and bend connected to an existing face along an edge. In the Design workspace, switch to the Sheet Metal toolbar.The Fusion Sheet Metal skill path gives you the fundamentals for working with sheet metal. Learn to create flat patterns from 3D models, work with all sorts of bends, customize your materials, and practice the principles of manufacturing and begin applying your new skills to real-world projects.Create a sheet metal component using Fusion.

sheet metal fusion tutorial

On the flux core chart, you can also find the voltage and wire speed settings for using a MIG welder with 0.035 ” inch wire. For instance, a volt setting and wire-speed of 19 and 340 works well with 8mm worth of metal.

autodesk fusion sheet metal|sheet metal fusion tutorial