cnc machine setup and operation Follow these steps to set up your SYIL CNC machine for operation: Ensure the machine is placed on a stable and level surface. Connect the machine to a power source and ensure it is properly grounded. Specialties: Providing superior commercial HVAC services for the California Bay Area. United Mechanical Inc. "Taking Excellence Personally. " Established in 2003. We started United Mechanical with a simple vision-- adopt the best values, empower the best people and strive for excellence. With our united group of talented employees, quality vendors, exceptional .

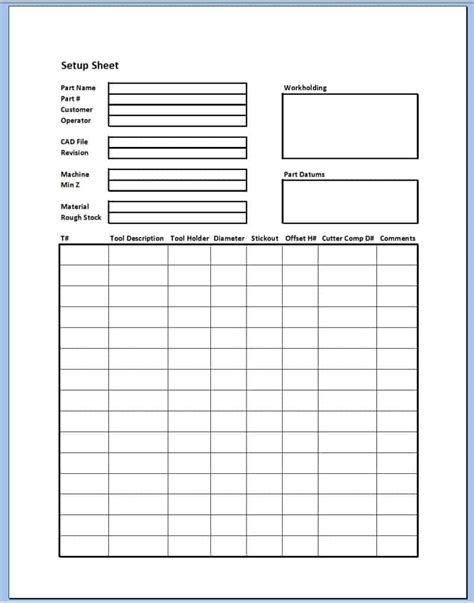

0 · cnc tool set up sheet

1 · cnc machines for dummies

2 · cnc machine setup sheet template

3 · cnc machine setup checklist

4 · cnc machine set up sheet

5 · cnc machine process step by

6 · cnc machine operating instructions

7 · cnc lathe setup sheet

Understanding the purpose and types of junction boxes is essential for maintaining a reliable electrical infrastructure in any property. Properly installed junction boxes play a vital role in ensuring the safety and efficiency of electrical connections, making them an indispensable component of modern construction and infrastructure.

Follow these steps to set up your SYIL CNC machine for operation: Ensure the machine is placed on a stable and level surface. Connect the machine to a power source and ensure it is properly grounded.

This step is essential because it ensures the safety of the CNC machine operator and the effective operation of the device. We at CAMaster prepared this guide to help you with .

In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your .

Elevate your career with our CNC Machine Operator Guide, featuring key skills, training insights, and job essentials for machining precision.

In this article, we will provide a step-by-step guide on how to set up a CNC milling machine, covering everything from initial inspection to the first cut. The first step in setting up a CNC milling machine is to inspect the .

To operate a CNC machine, you need to first understand the software that controls it. Take the time to get acquainted with the specific software package used by your CNC machine manufacturer. Read the user manual, .Learn how to create a setup sheet for your CNC machines with our step-by-step guide. Improve your workflow and productivity today!Setup and Operation. The setup and operation of a CNC machine is a process with multiple steps that demands meticulous attention to detail. Before starting operations, the CNC machinist . Are you new to operating a CNC lathe machine and looking for a step-by-step guide to help you get started? This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to .

In this blog post, we will explore the essential techniques that every CNC machine setup operator should know. From understanding machine components and tooling selection to machine .Follow these steps to set up your SYIL CNC machine for operation: Ensure the machine is placed on a stable and level surface. Connect the machine to a power source and ensure it is properly grounded. This step is essential because it ensures the safety of the CNC machine operator and the effective operation of the device. We at CAMaster prepared this guide to help you with CNC machine setup. Created for beginners and experienced professionals alike, it provides clear, step-by-step instructions.

In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your understanding of this fascinating field. CNC, or Computer Numerical Control, machining refers to the process of using computers to control machine tools. Elevate your career with our CNC Machine Operator Guide, featuring key skills, training insights, and job essentials for machining precision. In this article, we will provide a step-by-step guide on how to set up a CNC milling machine, covering everything from initial inspection to the first cut. The first step in setting up a CNC milling machine is to inspect the machine for any damage or wear. This includes checking the spindle, tool holders, and workholding devices. To operate a CNC machine, you need to first understand the software that controls it. Take the time to get acquainted with the specific software package used by your CNC machine manufacturer. Read the user manual, watch tutorial videos, and explore the different features and functions. CNC programming is a crucial skill for operating a CNC machine.

Learn how to create a setup sheet for your CNC machines with our step-by-step guide. Improve your workflow and productivity today!

buyers electrical junction box w/ 7 color coded terminals

Setup and Operation. The setup and operation of a CNC machine is a process with multiple steps that demands meticulous attention to detail. Before starting operations, the CNC machinist operator turns on the power and controls the machine, establishing its starting position for .

Are you new to operating a CNC lathe machine and looking for a step-by-step guide to help you get started? This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to programming and running the machine. Get expert advice and tips to ensure a smooth and successful setup of your CNC lathe machine.In this blog post, we will explore the essential techniques that every CNC machine setup operator should know. From understanding machine components and tooling selection to machine calibration and programming considerations, we will cover it all.

cnc tool set up sheet

Follow these steps to set up your SYIL CNC machine for operation: Ensure the machine is placed on a stable and level surface. Connect the machine to a power source and ensure it is properly grounded. This step is essential because it ensures the safety of the CNC machine operator and the effective operation of the device. We at CAMaster prepared this guide to help you with CNC machine setup. Created for beginners and experienced professionals alike, it provides clear, step-by-step instructions.In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your understanding of this fascinating field. CNC, or Computer Numerical Control, machining refers to the process of using computers to control machine tools.

Elevate your career with our CNC Machine Operator Guide, featuring key skills, training insights, and job essentials for machining precision. In this article, we will provide a step-by-step guide on how to set up a CNC milling machine, covering everything from initial inspection to the first cut. The first step in setting up a CNC milling machine is to inspect the machine for any damage or wear. This includes checking the spindle, tool holders, and workholding devices. To operate a CNC machine, you need to first understand the software that controls it. Take the time to get acquainted with the specific software package used by your CNC machine manufacturer. Read the user manual, watch tutorial videos, and explore the different features and functions. CNC programming is a crucial skill for operating a CNC machine.Learn how to create a setup sheet for your CNC machines with our step-by-step guide. Improve your workflow and productivity today!

Setup and Operation. The setup and operation of a CNC machine is a process with multiple steps that demands meticulous attention to detail. Before starting operations, the CNC machinist operator turns on the power and controls the machine, establishing its starting position for . Are you new to operating a CNC lathe machine and looking for a step-by-step guide to help you get started? This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to programming and running the machine. Get expert advice and tips to ensure a smooth and successful setup of your CNC lathe machine.

cnc machines for dummies

cnc machine setup sheet template

Sheet Metal Union Practice Test. Sheet Metal Union Apprenticeship Overview. Duration: Typically 4-5 years. Structure: Integrates hands-on work experience with classroom education. On-the-Job Training: Experience: Work under skilled journeymen to learn tasks like cutting, shaping, and installing sheet metal.

cnc machine setup and operation|cnc tool set up sheet