best cnc slant-type bed lathe machine For example, the KLR-200SM horizontal turning center from Kent USA has a 45° slant bed. An 8″ chuck machine, it has a 10.2″ diameter turning capacity and accommodates parts up to 19.5″ long. It also boasts a one-piece Meehanite .

Transform the performance and looks of your stock 1/10-scale Slash 2WD truck with our new Billet Machined LCG Chassis Conversion Set.

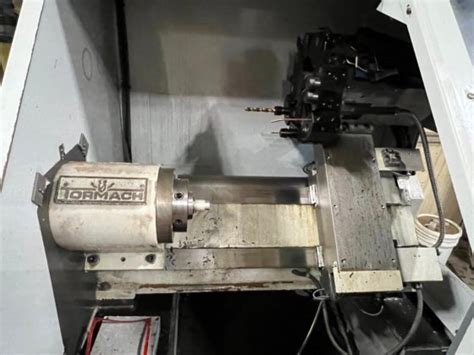

0 · tormach slant pro 15

1 · tormach slant 15 lathe

2 · tormach lathe price

3 · tormach lathe for sale

4 · tormach 15l for sale

5 · small footprint cnc lathe

6 · slant bed cnc machine

7 · 15l slant pro cnc lathe

The common terms for exterior trim include fascia, soffit, cornice, trim board, and window trim. How do you Paint Exterior Trim like a Pro? Apply two coats of paint using high-quality materials and tools, and make sure your brush strokes are even and smooth.

Our high-performance CNC slant bed lathes have a compact design and are perfect for fast chip removal and high precision. Request a quote!If you're looking to bring part production in-house, expand a CNC education program, or fulfill orders, the Tormach 15L Slant-PRO is an affordable option featuring a compact, powerful slant .

CNC Slant Bed Lathes. These lathes are used in the automotive industry, mechanical engineering or medical technology, among others. The compact design of a slant bed lathe is optimized for .Clausing/Colchester B Series Typhoon Slant Bed CNC Lathe, Boxed X,Z Ways, 26.37” Swing over bed, 21.25” swing over saddle, 11.81” turning diameter, 10/15 Hp Spindle motor, 4200 . Slant bed and flatbed CNC lathe machines are two common configurations used in the manufacturing industry, each offering distinct advantages and applications. Here’s a comparison of the two: In a slant bed .

For example, the KLR-200SM horizontal turning center from Kent USA has a 45° slant bed. An 8″ chuck machine, it has a 10.2″ diameter turning capacity and accommodates parts up to 19.5″ long. It also boasts a one-piece Meehanite .CNC Slant Bed Lathes. These lathes are used in the automotive industry, mechanical engineering or medical technology, among others. The compact design of a slant bed lathe is optimized for .

Slant bed CNC Lathe. Compared with the flat bed CNC lathe, the slant bed design has better chip removal ability. The independent tailstock and steady rest slide ways provide more variable .

In this article, I discuss the ins and outs of the two main bed designs for CNC lathe machines: the true slant bed and the flatbed “flying wedge” configurations.Gang Type Tools Slant Bed CNC Lathe. GT Series is known for their precision turning capabilities. With a slant bed design, these lathes offer increased stability and rigidity during .Our high-performance CNC slant bed lathes have a compact design and are perfect for fast chip removal and high precision. Request a quote!

If you're looking to bring part production in-house, expand a CNC education program, or fulfill orders, the Tormach 15L Slant-PRO is an affordable option featuring a compact, powerful slant-bed CNC lathe that operates on single-phase power.

CNC Slant Bed Lathes. These lathes are used in the automotive industry, mechanical engineering or medical technology, among others. The compact design of a slant bed lathe is optimized for good chip removal and offers high stiffness and precision. As a CNC slant bed lathe it is particularly suitable for reliable and efficient turning in series.Clausing/Colchester B Series Typhoon Slant Bed CNC Lathe, Boxed X,Z Ways, 26.37” Swing over bed, 21.25” swing over saddle, 11.81” turning diameter, 10/15 Hp Spindle motor, 4200 rpm, 8” hydraulic chuck, 2.04” bar capacity and 2.59” spindle bore, A2-6 spindle nose, manual tailstock w/3.54” quill diameter and 5 morse taper bore, live tool turret, Y Axis, 230/460 Volts, 3 Phase Slant bed and flatbed CNC lathe machines are two common configurations used in the manufacturing industry, each offering distinct advantages and applications. Here’s a comparison of the two: In a slant bed CNC lathe, the bed is angled or slanted, typically at around a 30 to 45-degree angle.For example, the KLR-200SM horizontal turning center from Kent USA has a 45° slant bed. An 8″ chuck machine, it has a 10.2″ diameter turning capacity and accommodates parts up to 19.5″ long. It also boasts a one-piece Meehanite casting for superior rigidity and vibration dampening.

CNC Slant Bed Lathes. These lathes are used in the automotive industry, mechanical engineering or medical technology, among others. The compact design of a slant bed lathe is optimized for good chip removal and offers high stiffness and precision. As a CNC slant bed lathe it is particularly suitable for reliable and efficient turning in series.

Slant bed CNC Lathe. Compared with the flat bed CNC lathe, the slant bed design has better chip removal ability. The independent tailstock and steady rest slide ways provide more variable long-parts processing capabilities, and the automatic loading and unloading system can be integrated to provide better production volume.In this article, I discuss the ins and outs of the two main bed designs for CNC lathe machines: the true slant bed and the flatbed “flying wedge” configurations.Gang Type Tools Slant Bed CNC Lathe. GT Series is known for their precision turning capabilities. With a slant bed design, these lathes offer increased stability and rigidity during machining, resulting in exceptional accuracy and surface finish.

Our high-performance CNC slant bed lathes have a compact design and are perfect for fast chip removal and high precision. Request a quote!

If you're looking to bring part production in-house, expand a CNC education program, or fulfill orders, the Tormach 15L Slant-PRO is an affordable option featuring a compact, powerful slant-bed CNC lathe that operates on single-phase power.

CNC Slant Bed Lathes. These lathes are used in the automotive industry, mechanical engineering or medical technology, among others. The compact design of a slant bed lathe is optimized for good chip removal and offers high stiffness and precision. As a CNC slant bed lathe it is particularly suitable for reliable and efficient turning in series.Clausing/Colchester B Series Typhoon Slant Bed CNC Lathe, Boxed X,Z Ways, 26.37” Swing over bed, 21.25” swing over saddle, 11.81” turning diameter, 10/15 Hp Spindle motor, 4200 rpm, 8” hydraulic chuck, 2.04” bar capacity and 2.59” spindle bore, A2-6 spindle nose, manual tailstock w/3.54” quill diameter and 5 morse taper bore, live tool turret, Y Axis, 230/460 Volts, 3 Phase Slant bed and flatbed CNC lathe machines are two common configurations used in the manufacturing industry, each offering distinct advantages and applications. Here’s a comparison of the two: In a slant bed CNC lathe, the bed is angled or slanted, typically at around a 30 to 45-degree angle.

For example, the KLR-200SM horizontal turning center from Kent USA has a 45° slant bed. An 8″ chuck machine, it has a 10.2″ diameter turning capacity and accommodates parts up to 19.5″ long. It also boasts a one-piece Meehanite casting for superior rigidity and vibration dampening.CNC Slant Bed Lathes. These lathes are used in the automotive industry, mechanical engineering or medical technology, among others. The compact design of a slant bed lathe is optimized for good chip removal and offers high stiffness and precision. As a CNC slant bed lathe it is particularly suitable for reliable and efficient turning in series.Slant bed CNC Lathe. Compared with the flat bed CNC lathe, the slant bed design has better chip removal ability. The independent tailstock and steady rest slide ways provide more variable long-parts processing capabilities, and the automatic loading and unloading system can be integrated to provide better production volume.

In this article, I discuss the ins and outs of the two main bed designs for CNC lathe machines: the true slant bed and the flatbed “flying wedge” configurations.

tormach slant pro 15

how to run a dryer plug from your electrical box

how to replace junction box in ceiling

The #1 Source for professional grade treehouse supplies: hardware kits, treehouse plans, brackets, bolts, zip lines & more- every treehouse builder's best friend. We supply smiles!

best cnc slant-type bed lathe machine|tormach lathe price