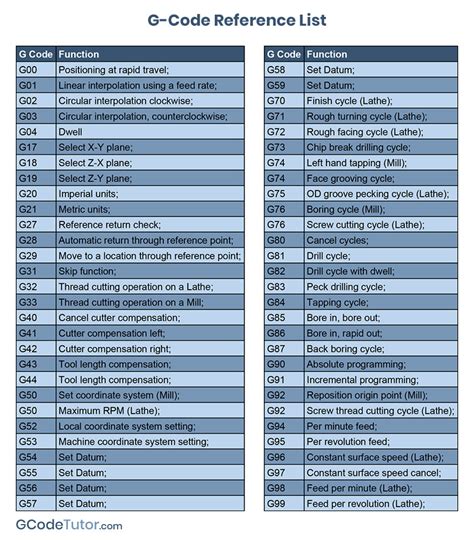

cnc lathe machine g codes A complete list of Centroid CNC lathe G Code. A given line of a program may contain more than one G-code. If several G-codes from one group are used in. Examine the Ford wipers wiring diagram below. First, notice that the wiper speed switch is now called a multi-function switch (MFS). It does not actually switch power to the wiper motor. It just acts as a signaling device to tell the Smart Junction Box .

0 · list of g codes cnc

1 · list of fanuc g codes

2 · cnc turning g code list

3 · cnc mill g code list

4 · cnc lathe g codes list

5 · cnc lathe g code examples

6 · cnc g code list download

7 · cnc g code chart

W.S.M. Fascia Gutter available in colorbond, zinc and galvanised at Wilsons Sheet Metals

Jun 26, 2024 G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands.Vertical Mills ; VF Series; Universal Machines; VR Series; VP-5 Prismatic; Pallet-Changing VMCs; Mini Mills; Mold Machines; High-Speed Drill Centers; Drill/ Tap/ Mill Series

metal fabricators in missouri

CNC G-codes & M Codes for milling and turning with explanations, . A complete list of Centroid CNC lathe G Code. A given line of a program may contain more than one G-code. If several G-codes from one group are used in. This article introduces lists of G-codes used to program CNC machines for milling and turning jobs on machines like CNC mills, lathes, machining centers, etc. Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections .

Learn everything about G-code and M-code, essential languages for CNC machine operations. Our comprehensive guide covers basic structures, common commands, examples, and the role of AI in CNC programming.

G-Code is the most common programming language. A G-Code in CNC Programming works like a controller and dictator. It controls the machine’s movement and dictates how and where it should move to formulate the end . These are the common g-codes for CNC Lathes and turning. Code categories are the groupings for the g-code Wizard (type Ctrl+G for the Wizard). G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands.

Vertical Mills ; VF Series; Universal Machines; VR Series; VP-5 Prismatic; Pallet-Changing VMCs; Mini Mills; Mold Machines; High-Speed Drill Centers; Drill/ Tap/ Mill SeriesCNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machinesA complete list of Centroid CNC lathe G Code. A given line of a program may contain more than one G-code. If several G-codes from one group are used in.

This article introduces lists of G-codes used to program CNC machines for milling and turning jobs on machines like CNC mills, lathes, machining centers, etc.

Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections with G20 and G21 for Inches and Millimeters, respectively.Learn everything about G-code and M-code, essential languages for CNC machine operations. Our comprehensive guide covers basic structures, common commands, examples, and the role of AI in CNC programming. G-Code is the most common programming language. A G-Code in CNC Programming works like a controller and dictator. It controls the machine’s movement and dictates how and where it should move to formulate the end CNC machined product. M-Code is used for specific applications.

These are the common g-codes for CNC Lathes and turning. Code categories are the groupings for the g-code Wizard (type Ctrl+G for the Wizard).

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands.Vertical Mills ; VF Series; Universal Machines; VR Series; VP-5 Prismatic; Pallet-Changing VMCs; Mini Mills; Mold Machines; High-Speed Drill Centers; Drill/ Tap/ Mill Series

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machinesA complete list of Centroid CNC lathe G Code. A given line of a program may contain more than one G-code. If several G-codes from one group are used in. This article introduces lists of G-codes used to program CNC machines for milling and turning jobs on machines like CNC mills, lathes, machining centers, etc.

Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections with G20 and G21 for Inches and Millimeters, respectively.Learn everything about G-code and M-code, essential languages for CNC machine operations. Our comprehensive guide covers basic structures, common commands, examples, and the role of AI in CNC programming.

metal fabricators detroit

list of g codes cnc

metal fabricators cleveland tennessee

list of fanuc g codes

cnc turning g code list

This kit includes the Hold It Mate 36" Long Mounting Rail plus (2) Bottom adjustable Planter box Brackets that simply snap on to the mounting rail. The (2) bottom adjustable brackets are adjustable from 6" to 10" wide at the bottom, also perfect for shallower and wider boxes.

cnc lathe machine g codes|cnc lathe g code examples