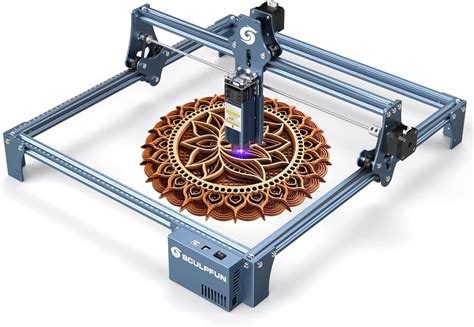

cnc laser machining Both laser cutters and CNC machines are subtractive manufacturing processes that use computer numerical control (CNC). This means you use design software to design the part, and control software to generate the desired tool . $1,600.00

0 · laser cnc machines for woodworking

1 · laser cnc machine hobby

2 · laser cnc machine for wood

3 · highest rated industrial laser engraver

4 · best laser for cnc machine

5 · best laser engravers for hobbyists

6 · best laser engraver for home use

7 · best laser cutting machine for hobbyist

$149.00

Both laser cutters and CNC machines are subtractive manufacturing processes that use computer numerical control (CNC). This means you use design software to design the part, and control software to generate . A laser cutter is a machine that uses a laser beam to cut or engrave materials such as wood, plastic, or metal. It works by directing the laser beam through a series of mirrors and lenses to focus the energy onto a small spot, melting or vaporizing the material based on instructions from a computer.

Having tested many of the best laser cutters and engravers, we created our recommendations for the best laser cutting machines in each price range, for each use, and more. I also link to some of my detailed hands-on reviews, such as for the Snapmaker 2.0 , Ortur Laser Master 3 , and more.

cnc laser cutting machine programming pdf

Both laser cutters and CNC machines are subtractive manufacturing processes that use computer numerical control (CNC). This means you use design software to design the part, and control software to generate the desired tool .One machining technology that has been helping machinists satisfy these requirements today is the CNC laser cutter. A CNC laser cutter is a piece of computer numerical control (CNC) equipment that uses a focused, high-powered laser beam to mark, cut, or engrave a material to form custom shapes.The LASERTEC series opens up new economic opportunities in laser precision machining. Now, you can use lasers to execute technical surface structures, press stamps, engravings, labels or drilling in workpieces with the same precision as is required. A CNC laser cutter is a machine that is equipped with a computer numerical control (CNC) system, which uses a focused beam of light to cut or engrave materials very accurately. The process starts with a laser source – typically CO2, .

Whether you're in manufacturing, crafting, or prototyping, understanding how to operate a CNC laser cutter is essential. This comprehensive guide will walk you through the entire process, from initial setup to advanced techniques, ensuring you can harness the full potential of this powerful machine. Understanding CNC Laser Cutters

laser cnc machines for woodworking

A CNC laser is a cutting-edge technology that uses a high-powered laser beam to cut and engrave various materials with precision. By focusing the laser beam onto the material, CNC lasers can create rapid melting or vaporization, resulting in . CNC laser machining is a specific type of CNC machining that employs a laser beam to cut through materials with extreme precision. The process utilizes a high-power laser to melt, burn, or vaporize material, leaving behind a clean and precise cut.

Tsugami’s LaserSwiss machines combine the precision of a Swiss turning center with a fully integrated laser cutting system to improve part quality, minimize part handling, eliminate secondary operations, and accelerate production to unimaginable speeds. A laser cutter is a machine that uses a laser beam to cut or engrave materials such as wood, plastic, or metal. It works by directing the laser beam through a series of mirrors and lenses to focus the energy onto a small spot, melting or vaporizing the material based on instructions from a computer.

Having tested many of the best laser cutters and engravers, we created our recommendations for the best laser cutting machines in each price range, for each use, and more. I also link to some of my detailed hands-on reviews, such as for the Snapmaker 2.0 , Ortur Laser Master 3 , and more.

Both laser cutters and CNC machines are subtractive manufacturing processes that use computer numerical control (CNC). This means you use design software to design the part, and control software to generate the desired tool .One machining technology that has been helping machinists satisfy these requirements today is the CNC laser cutter. A CNC laser cutter is a piece of computer numerical control (CNC) equipment that uses a focused, high-powered laser beam to mark, cut, or engrave a material to form custom shapes.

The LASERTEC series opens up new economic opportunities in laser precision machining. Now, you can use lasers to execute technical surface structures, press stamps, engravings, labels or drilling in workpieces with the same precision as is required.

A CNC laser cutter is a machine that is equipped with a computer numerical control (CNC) system, which uses a focused beam of light to cut or engrave materials very accurately. The process starts with a laser source – typically CO2, . Whether you're in manufacturing, crafting, or prototyping, understanding how to operate a CNC laser cutter is essential. This comprehensive guide will walk you through the entire process, from initial setup to advanced techniques, ensuring you can harness the full potential of this powerful machine. Understanding CNC Laser Cutters A CNC laser is a cutting-edge technology that uses a high-powered laser beam to cut and engrave various materials with precision. By focusing the laser beam onto the material, CNC lasers can create rapid melting or vaporization, resulting in .

CNC laser machining is a specific type of CNC machining that employs a laser beam to cut through materials with extreme precision. The process utilizes a high-power laser to melt, burn, or vaporize material, leaving behind a clean and precise cut.

cnc laser cutting machine price in india

laser cnc machine hobby

laser cnc machine for wood

cnc laser engraving machine manufacturer

highest rated industrial laser engraver

Reduce the cost of equipment and labor using short runs of multi-core cables connected directly to Smart Junction Boxes in the field. Installed directly in the field, Smart Junction boxes can reduce equipment room footprint between 90% and 95%.

cnc laser machining|laser cnc machine for wood