class 1 division 1 electrical enclosure Conduit seals are required in all conduit entrances for Class I, Division 1, Group B hazardous areas, and for EJB361208, EJB361808, EJB361810, EJB362408 and all Style D enclosures . In this article, we will discuss the different types of trims for metal roofing, why they are valuable, and the factors to consider before choosing one for your roofing system. What Is Metal Roofing Trim? A metal roofing trim is not just a roofing accessory but a vital tool in preventing water damage.

0 · class 2 div 1 enclosure

1 · class 1 division 2 requirements

2 · class 1 division 2 locations

3 · class 1 div 2 wiring

4 · class 1 div 2 specifications

5 · class 1 div 2 rules

6 · class 1 div 2 receptacle

7 · class 1 div 2 code

CNC (Computer Numerical Control) machining technology plays a pivotal role in modern manufacturing, and inserts, as a key tool in CNC machining, directly impact machining efficiency and product quality. This article will detail the types, materials, machining methods, coatings, advantages, hardness, and lifespan of inserts. Types of Inserts

Rely on nVent HOFFMAN to protect your electrical controls in Division 1 or Zone 1 areas with flameproof and explosion proof enclosures. Our enclosures also improve the reliability of panels in hazardous locations with purge and pressurization solutions.

solder for galvanized sheet metal

EJB enclosures are globally certified for use in worldwide applications. They are listed for Class I, Division 1 and Class II, Division 1 hazardous areas, and they also have IECEx and ATEX .In Class I locations, an installation must be classified as using the division classification system meeting paragraphs (c), (d), (e), and (f) of this section or using the zone classification system meeting paragraph (g) of this section.Type 1 Enclosures constructed for indoor use to provide a degree of protection to personnel against access to hazardous parts and to provide a degree of protection of the equipment .

class 2 div 1 enclosure

Conduit seals are required in all conduit entrances for Class I, Division 1, Group B hazardous areas, and for EJB361208, EJB361808, EJB361810, EJB362408 and all Style D enclosures . NEMA 1. General-purpose and for indoor use. Type 1 provides a degree of protection to the equipment inside the enclosure against the ingress of solid foreign objects, .

.00.28.40 Provide electrical controls (e.g., switches, breakers), control transformers, and resistors with enclosures identified for use in Class I locations. In a Div. 2 location, you can use a general enclosure under certain conditions .

class 1 division 2 requirements

class 1 division 2 locations

Explosion-proof circuit breakers, disconnects, manual starters and combination starter enclosures are all designed for Motor Control in Class I, Div. 1 & 2 applications with varying electrical ratings to suit your application requirements.

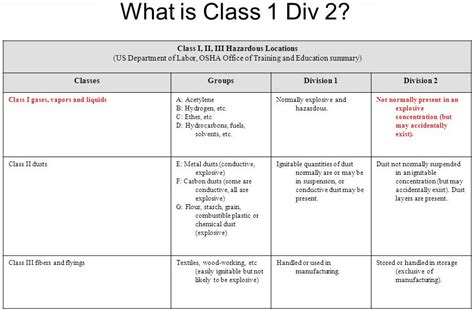

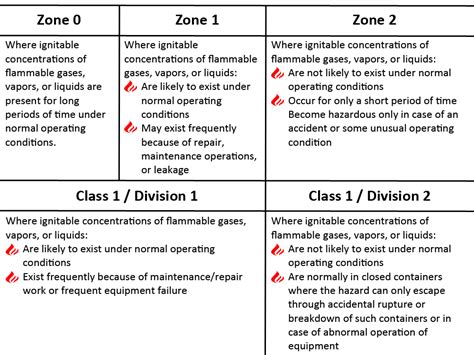

For example, Class I Division 1 indicates a location where explosive gas-air mixtures are likely to occur during normal operations. Hazardous location enclosures also encompass explosion .

9.989.28.65.41

2.04a booth must be rated for Class I or II, Division I. Fixtures that are recessed, certified Division II and specifically listed for paint spray booths may also be used.

An enclosure with a UL stamp of being rated for Class I, Div 1 does NOT mean that it is approved for a Zone 1, Group IIA/B, T4 area. Even with same temperature and gas ratings, the approval stamp on the equipment must match the area rating. NFPA 820, Table 4.2 indicates that a Residential Wastewater Pumping Station Wetwell is a Cass 1, Division 2 Location. If I specify Class 1, Division 2 rated submersible pumps, do I have to ventilate the wetwell or do I have to use a Combustable Gas Detector(CGD? If a CGD is used, does it have. The system consist of a small 1" gear pump driven by a 1.5HP TEFC motor that is installed inside of an NEMA 4X enclosure with no ventilation, the pump draws fuel into the enclosure through 1" brass pipe fittings through the pump, discharging the fuel through a centrifuge fuel purifier and then through a fuel Mag treating for microbiological .

Our sales force year in and year out seem to get a mixed bag of opinion on this, but whenever it seems that the opinion shared is, "I believe Class 1, Div 1 is going away and you will see the whole market switch to Intrinsically Safe, Purge, etc. away from explosion-proof", we seem to sell more Class 1, Div 1 enclosures. Class 1, Division 2 .

class 1 div 2 wiring

RE: Class 1 Div 1/2 enclosure question controlnovice (Electrical) 20 Aug 09 17:07 I think NEC 500.8(D)(1) states that Listed conduit, conduit fittings, or cable fittings shall be used for equipment provided with threaded entries. There are 5 requirements that must ALL be met in order to use this exception. The fifth requirement for this exception says: "The conduit system segment is sealed at its entry to each enclosure or fitting housing terminals, splices, or taps in Class I, Division 2 locations." Hi, I have a question in regards to wiring in a class 1 division 1 environment. I currently have an equipment control panel rated for class 1 div 1 enviroment, and speculation has been raised about the suitability of the power cord. The plug on the cord is an abbleton class 1 . Where gas-mixing machines are installed in well-ventilated areas, the type of electrical equipment shall be in accordance with NFPA70,National Electrical Code, for general service conditions unless other hazards in the area prevail. Where gas-mixing machines are installed in small detached buildings or cutoff rooms, the electrical equipment and .

My motor supplier informed me that anti condensation heaters are not available for Class 1 Division 1 motors. The client specified space heaters for all motors. I went through the NEC NFPA 70 Article 500 but they only mention space heaters for Class 1 Division 2 motors however there is no mention that space heaters can not be used in Class 1 .

The only exceptions occur when all devices in the intrinsically safe circuit are: 1) hermetically sealed, or 2) immersed in oil, or 3) enclosed in a factory-sealed (so labeled AND properly labelled for the EXACT classification including Class, Division or Zone, and Gas designation) enclosure, or 4) "nonincendive" circuits. 3. An enclosure with a UL stamp of being rated for Class I, Div 1 does NOT mean that it is approved for a Zone 1, Group IIA/B, T4 area. Even with same temperature and gas ratings, the approval stamp on the equipment must match the area rating. NFPA 820, Table 4.2 indicates that a Residential Wastewater Pumping Station Wetwell is a Cass 1, Division 2 Location. If I specify Class 1, Division 2 rated submersible pumps, do I have to ventilate the wetwell or do I have to use a Combustable Gas Detector(CGD? If a CGD is used, does it have.

The system consist of a small 1" gear pump driven by a 1.5HP TEFC motor that is installed inside of an NEMA 4X enclosure with no ventilation, the pump draws fuel into the enclosure through 1" brass pipe fittings through the pump, discharging the fuel through a centrifuge fuel purifier and then through a fuel Mag treating for microbiological . Our sales force year in and year out seem to get a mixed bag of opinion on this, but whenever it seems that the opinion shared is, "I believe Class 1, Div 1 is going away and you will see the whole market switch to Intrinsically Safe, Purge, etc. away from explosion-proof", we seem to sell more Class 1, Div 1 enclosures. Class 1, Division 2 . RE: Class 1 Div 1/2 enclosure question controlnovice (Electrical) 20 Aug 09 17:07 I think NEC 500.8(D)(1) states that Listed conduit, conduit fittings, or cable fittings shall be used for equipment provided with threaded entries. There are 5 requirements that must ALL be met in order to use this exception. The fifth requirement for this exception says: "The conduit system segment is sealed at its entry to each enclosure or fitting housing terminals, splices, or taps in Class I, Division 2 locations."

Hi, I have a question in regards to wiring in a class 1 division 1 environment. I currently have an equipment control panel rated for class 1 div 1 enviroment, and speculation has been raised about the suitability of the power cord. The plug on the cord is an abbleton class 1 . Where gas-mixing machines are installed in well-ventilated areas, the type of electrical equipment shall be in accordance with NFPA70,National Electrical Code, for general service conditions unless other hazards in the area prevail. Where gas-mixing machines are installed in small detached buildings or cutoff rooms, the electrical equipment and . My motor supplier informed me that anti condensation heaters are not available for Class 1 Division 1 motors. The client specified space heaters for all motors. I went through the NEC NFPA 70 Article 500 but they only mention space heaters for Class 1 Division 2 motors however there is no mention that space heaters can not be used in Class 1 .

class 1 div 2 specifications

In this article, we explore the top CNC milling machine manufacturers, highlighting their innovations and contributions. You’ll learn about industry leaders like Mazak, Okuma, and others, and discover how their .

class 1 division 1 electrical enclosure|class 1 div 2 code