6061 aluminum cnc machining factories Explore top-tier aluminum 6061 T6 CNC machining services. Experience precision, durability, and efficiency tailored for your project's unique needs. . • Pry-resistant welded construction with 3-point locking system. • Flush bottom shelf for easy loading. • Ships fully assembled. • Custom solutions, colors, and locking systems are available. • 99.9% customer acceptance rate, building cabinets and relationships that last a .

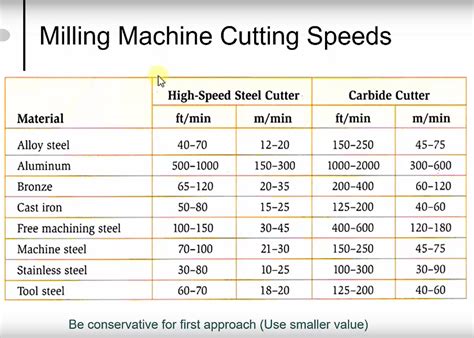

0 · surface speed for 6061 aluminum

1 · sfm range for 6061 aluminum

2 · recommended cutting speed for aluminum

3 · cutting speed for 6061 aluminum

4 · casting 6061 aluminum

5 · aluminum machinability chart

6 · aluminum alloy machinability chart

7 · 6061 aluminum machinability chart

In this blog post, we will explore the key factors that affect MIG welding sheet metal, including wire size, gas selection, amperage, and voltage. We will also provide tips and best practices to help you achieve optimal welding results.

Aluminum 6061 is used where appearance and better corrosion resistance with good strength are required. This high volume production job was ordered in thousands of pieces. We got the .Explore top-tier aluminum 6061 T6 CNC machining services. Experience precision, durability, and efficiency tailored for your project's unique needs. .

Aluminum alloy 6061 is one of the most extensively used in 5 axis precision machining in cnc machine shop industry. Aluminum 5052 alloy is a non-heat treatable alloy with good corrosion .Aluminum 6061 is the most popular aluminum alloy for CNC milling. It’s a versatile and easy-to-machine metal. It has a good strength-to-weight ratio, low cost, .

When needed, we can offer 6061 aluminum CNC machining guidance on an engineer’s designs to ensure perfection. Our workshop turns out 6061 aluminum CNC machining prototypes, .Aluminum 6061 is used where appearance and better corrosion resistance with good strength are required. This high volume production job was ordered in thousands of pieces. We got the cycle time down to minutes for a complete part while holding all tolerances.

Pen Manufacturing offers aluminum 6061 CNC machining, which is the most versatile of all the aluminum alloys because of its clean surface finish. Call us!Explore top-tier aluminum 6061 T6 CNC machining services. Experience precision, durability, and efficiency tailored for your project's unique needs. Get started today!

Aluminum alloy 6061 is one of the most extensively used in 5 axis precision machining in cnc machine shop industry. Aluminum 5052 alloy is a non-heat treatable alloy with good corrosion resistance, especially to salt water. The machinability of Aluminum 5052 alloy is rated as fair.

Aluminum 6061 is the most popular aluminum alloy for CNC milling. It’s a versatile and easy-to-machine metal. It has a good strength-to-weight ratio, low cost, recyclability, non-magnetic, heat treatable, and natural corrosion resistance.When needed, we can offer 6061 aluminum CNC machining guidance on an engineer’s designs to ensure perfection. Our workshop turns out 6061 aluminum CNC machining prototypes, production manufacturing, PEEK machined parts and specialty projects.Aluminum alloys, such as 6061-T651, 7075-T651, and 2024-T351, are commonly used in CNC machining because they offer a good balance of strength, machinability, and cost. Aluminum parts can be found everywhere, in a range of industries, especially automotive, aerospace, industrial equipment and machinery, and consumer and computer electronics.Aluminum 6061 is one of the most widely used aluminum alloys. Its weld-ability and formability make it suitable for many general-purpose applications. Its high strength and corrosion resistance lend type 6061 alloy particularly useful in architectural, structural, and motor vehicle applications.

Aluminum 6061 (CNC) is the most popular aluminum alloy. It has good strength-to-weight ratio, excellent machinability and natural corrosion resistance. 20% off your first order.

cleaner for cnc machines

surface speed for 6061 aluminum

6061 is a common aluminum alloy produced by heat treatment and stretching process. With its high strength and corrosion resistance, CNC machining 6061 aluminum products extensively used in industrial structural and more fields.Aluminum 6061 is used where appearance and better corrosion resistance with good strength are required. This high volume production job was ordered in thousands of pieces. We got the cycle time down to minutes for a complete part while holding all tolerances.

Pen Manufacturing offers aluminum 6061 CNC machining, which is the most versatile of all the aluminum alloys because of its clean surface finish. Call us!Explore top-tier aluminum 6061 T6 CNC machining services. Experience precision, durability, and efficiency tailored for your project's unique needs. Get started today!Aluminum alloy 6061 is one of the most extensively used in 5 axis precision machining in cnc machine shop industry. Aluminum 5052 alloy is a non-heat treatable alloy with good corrosion resistance, especially to salt water. The machinability of Aluminum 5052 alloy is rated as fair.

Aluminum 6061 is the most popular aluminum alloy for CNC milling. It’s a versatile and easy-to-machine metal. It has a good strength-to-weight ratio, low cost, recyclability, non-magnetic, heat treatable, and natural corrosion resistance.

When needed, we can offer 6061 aluminum CNC machining guidance on an engineer’s designs to ensure perfection. Our workshop turns out 6061 aluminum CNC machining prototypes, production manufacturing, PEEK machined parts and specialty projects.Aluminum alloys, such as 6061-T651, 7075-T651, and 2024-T351, are commonly used in CNC machining because they offer a good balance of strength, machinability, and cost. Aluminum parts can be found everywhere, in a range of industries, especially automotive, aerospace, industrial equipment and machinery, and consumer and computer electronics.Aluminum 6061 is one of the most widely used aluminum alloys. Its weld-ability and formability make it suitable for many general-purpose applications. Its high strength and corrosion resistance lend type 6061 alloy particularly useful in architectural, structural, and motor vehicle applications.

Aluminum 6061 (CNC) is the most popular aluminum alloy. It has good strength-to-weight ratio, excellent machinability and natural corrosion resistance. 20% off your first order.

sfm range for 6061 aluminum

cleaninf vintage metal milk box

Our interactive player makes it easy to find solutions to Welding 8th Edition problems you're working on - just go to the chapter for your book. Hit a particularly tricky question? Bookmark it to easily review again before an exam.

6061 aluminum cnc machining factories|surface speed for 6061 aluminum