mig welding wire size for sheet metal It’s recommended to use a .023- or .024-inch wire for most light gauge sheet metal work. When the material is 18-gauge and thicker, you may be able to use a .030-inch wire. To . A small metal household type junction box was mounted up under the trailer in front to house the connections between the trailer wiring and the pigtail and Battery. It was all put together with plastic twist on "Wire Nuts" used in houses.Our solutions are recognized for quality, performance and innovation leadership. Our growing portfolio of products and services shares our commitment to delivering an .

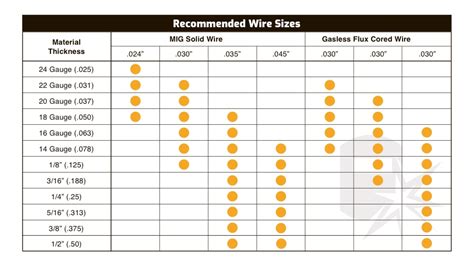

0 · welding wire diameter chart

1 · welding thickness chart

2 · welding mig wire size chart

3 · weld wire selection chart

4 · mig wire diameter chart

5 · mig welding wire size selection

6 · mig welding wire size explained

7 · mig welding sheet metal basics

Streamline your workflow storage with VWR Ultra- Low Temperature Upright Freezer.

The most common sizes for welding on sheet metal are 0.35 and 0.45. MIG Wire selection chart – See full-size version here. Wire Quantity. In making a MIG wire purchase, . The welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. It ensures optimal weld quality, appropriate amperage, and effective . A MIG wire size chart provides recommended wire diameters for different metal thicknesses. Standard sizes range from 0.023 to 0.045 inches for welding various metal . It’s recommended to use a .023- or .024-inch wire for most light gauge sheet metal work. When the material is 18-gauge and thicker, you may be able to use a .030-inch wire. To .

Mig welding, also known as Gas Metal Arc Welding (GMAW), is a popular method for welding sheet metal due to its speed and versatility. It uses a continuous solid wire electrode . The choice between 0.8 mm and 0.9 mm MIG wire depends on the thickness of the metal being welded. 0.8 mm wire is suitable for welding thin metal sheets up to 3 mm thick, while 0.9 mm wire is better suited for thicker metals .

Using 0.023, 0.024, and 0.030 in MIG solid wires for sheet metal is best. Also, avoid a 100% CO2 shielding gas because it amplifies penetration, which leads to burn-through. The best shielding gas for MIG welding thin mild . Browse suggested weld parameter settings for Stick Welding, TIG Welding, MIG (Solid-Wire) Welding and MIG (Flux-Core) Welding. They show .030 for 22 gauge.I have been using .035 on my panels.but it's a bit of work trying not to burn through..but I have been doing it directing the heat towards the new steel and letting it flow over. MIG wire sizes typically range from 0.023 to 0.045 inches, and selecting the appropriate size depends on the metal thickness being welded. The wire acts as the filler material that melts and joins metal pieces together during .

I do regularly see youtube videos on welding-themes. On one channel the maker is stating, on welding 0.6 mm sheet metal (car-stuff e.g.) you can only use 0.6 mm. wire, because when using 0.8 wire the heat needed for melting the wire would have melted/blown holes in the sheet. At first glance, this sounds logical, but is it true? And in this situation, a welder-setting of . Maybe you’re working in a factory that uses thin sheet metal or trying to make welding art at home. . Recommended MIG Wire Size (inches) 0.024: 0.020: 0.030: 0.023: 0.036: 0.025: 0.048: 0.030: 0.060: . Welding thin metal is sometimes harder than welding massive chunks because the likelihood of burning through and damaging the base metal .

I am about to start a new project using 16 gauge sheet metal and all I have for wire at the moment is .030. Would a smaller wire be better and if so how much better will it be and why. Also is there a difference in using .023 vs.025. I have a lincoln pro mig 180 and it states it can use .025 but I see .023 is a more popular wire size. Welding auto body sheet metal can present challenges for welders but Ron Covell is here to help mitigate warping with both MIG and TIG welding. Menu. Equipment. Welders; Wire Feeders; Plasma Cutters; Oxy-Fuel Equipment; Fume Extraction . Every welder has their own preferences for sheet metal. I’m using 0.023-inch ER 70 S-6 filler wire and . MIG welding is widely utilized for welding thin metals. Follow these step-by-step instructions to successfully perform MIG welding on thin materials: . Ensure that you use very thin wires when welding with delicate, thin sheet metal. Metal Thickness (inches) Recommended MIG Wire Size (inches) 0.024: 0.020: 0.030: 0.023: 0.036: 0.025: 0.048: 0 .

You can do a couple of things to combat this extra heat, the first of which is picking the right wire size. In general, don’t use a wire that is thicker than your sheet metal. If you’re welding 1mm thick steel sheet metal, then you’ll want to use an 0.6mm wire for the best results, although 0.8mm would also work. The thinner your wire .There seems to be much difference of opinions on which size wire works best on sheet metal (22 g- 18 g) I've always used .030 in my MM210, harris 20 gauge in my 110 machine. I was wondering what others opinions/results were with .023 or .030. Thanks DavidWhen it comes to wire selection for the MIG the rule of the thump is to avoid using filler metal that is thicker than the base metal. Most of the light gauge sheet metal work will require the use of .023- or .24- inch while if you have a sheet metal having a gauge of more than 18-gauge then a .030-inch wire would be the most ideal.

best way have a look on you tube loads of learning mig welding the reason people want to know about what amps the mig will work at yours sounds like some of the harbour freight ones that had offers on the amps are a bit high on the low end for car work hence you see the problem you may be able to weld ok on 3mm but not on .8mm the only way you .This chart is a helpful guide for choosing the correct wire size and type (solid or flux) of wire based on the thickness of the material being welded. All Categories. Welding . Welding. MIG Welding. Miller MIG Welders; ESAB MIG Welders; Lincoln MIG Welders; MIG Wire; MIG Consumables; . MIG Welding. Miller MIG Welders . I need to weld some 22 Gauge sheet metal with my Lincoln Easy Mig 180. Question is, does smaller wire burn hotter because there is less material going in to cool the puddle? If i look on the chart on the welder, it says to use settings 2-B for 22 gauge either .025 or .030 wire (100% co2). A hands on look at the two MIG welding wire sizes that I would recommend for most people.****Affordable self-paced welding courses taught by me****https://co.

Weld Wire If you are patching sheet metal I would use .018 wire, I have been welding for a very long time, pipe fitting and everything. On a smaller machine like a 120 volt/220volt MIG that would be the best, low heat and not a .

In doing some research about MIG welding sheet metal, I've noticed some folks recommend using .023 wire for vehicle applications of 16g - 20g sheet. I'm trying to understand the differences between .023 and .025 as it relates to the wire itself, tips, and drive roll. - . The filler metal deposition rate is slower than FCAW, but it’s less likely to burn through the thin sheet metal. There are many different sizes and MIG welding wire types. So, let’s quickly go through the MIG wire specs and .

Note: If you are ever uncertain about a particular wire’s characteristics, then your best bet will be to consult with the manufacturer’s recommendations. Choose a MIG Wire Size Suitable for Car Panels. The three most common wire sizes in MIG welding are 0.035″, 0.030″, and 0.023″. Of these, the smaller diameter wire has been accepted .A. Basics of Wire Feed Welding. Wire feed welding, also known as MIG (Metal Inert Gas) welding, involves the use of a wire that is fed continuously at a pre-set speed. This wire acts as both the electrode and the filler material, melting to form the weld as an inert gas shields it. For sheet metal what is the welding current needed. i see some machines with low of 15 amp, 20 amp 30 amp. . so for 1mm you should need around 40 amps but the voltage of your machine and wire size will also affect things. . If that question was aimed at me then I have not owned one but used to weld with a 400 amp 3 phase industrial mig and .

welding wire diameter chart

I need advice before I start (mess up) welding in a replacement outer panel on my van. I’ve cut the new panel to size and achieved a consistent 1mm gap except for one part probably about 10cm in length where the gap is about 2-3mm. I’m currently using 0.6mm wire would 0.8mm be better to fill. My little Lincoln 140c (120VAC) came with "smooth" rollers for .025/.030" AND .030" sized MIG process wire. Not to mentin a knurled .030"-.045" knurled "flux core" wire roller. That being said, I see many people here routinely talk about using either the .023/.025" wire diameter for a 120VAC welder or step up to the flux core .035" dimeter wire. The size of MIG welding wire you need depends on the thickness of the material you’re welding. As a general guideline, use 0.030-0.035 inch (0.8-0.9 mm) wire for common applications. . What size MIG wire is best for sheet metal? For sheet metal, use a smaller wire size like 0.023-0.030 inch (0.6-0.8 mm) for better control and less heat .

Mig welding sheet metal requires precision and control to prevent warping or burn-through. A thin wire and low heat settings are essential. Mig welding, also known as Gas Metal Arc Welding (GMAW), is a popular method for welding sheet metal due to .

Welders seeking the best MIG welding wire are often left confused by the number of options available to them - fortunately, it's quite easy to narrow down . Great for sheet metal applications or structural plate steels which are moderately rusted; . It shouldn’t come as a surprise to learn that the size of the welding wire matters. There . What is the preferred wire size for sheet metal? I have a miller 250 with .030 wire now. It works for sheet metal with the occasional "blow thru". I only do tacks and jump all around. . When welding sheet metal with mig, don't try to weld continuous beads - instead use multiple tacks - weld a few tacks over the length of a seam, then go back . In this comprehensive guide, we'll delve into the intricacies of MIG welding sheet metal and explore the ideal settings for different metal thicknesses. From. Skip to content. November 14, 2024. Fit Welding. Your Welding Solution. Home; . Utilizing a smaller diameter welding wire, such as 0.023 inches, offers better control and precision when .

akdy 30 inch under cabinet stainless steel range hood 1802sf

akron explosion proof junction box

Click on your Model. Accessories; Body Components; Bumpers; Brakes & Wheels; Door Components ›

mig welding wire size for sheet metal|welding mig wire size chart