electrical box hood system wiring Range hoods do not draw more than 7 amps at best. For lighter units, you can expect around 2-4 amps. A 20-amp circuit breaker is suitable for a range hood. This way other smaller . See more Common shiny silk fabric types include: Charmeuse – Lightweight, flowing satin-weave silk. Dupioni – Made from twisted silk fibers, resulting in a textured, shiny surface. Taffeta – Crisp, smooth silk fabric with a stiff drape. Used for formalwear. Satin – Has a satin weave and intense luster. Used for evening gowns and lingerie.

0 · wiring range hood circuit

1 · range hood wiring instructions

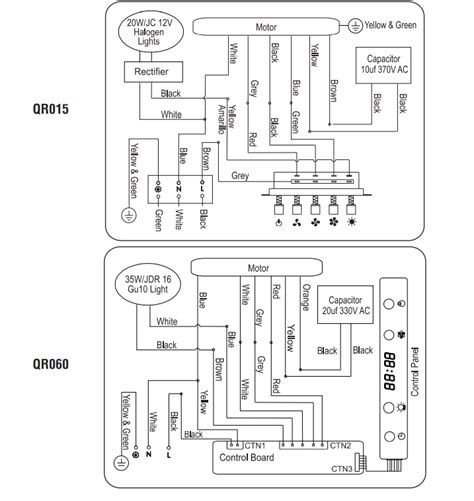

2 · range hood wiring diagram

3 · range hood wiring amps

4 · kitchen range hood wiring diagram

5 · kitchen hood wiring diagram

6 · how to wire a range hood

7 · electric range hood wiring

There are many types of boxes used for various functions in PV applications. This article will serve as a guide to the most commonly used ones. In the image below, we see the PV array feeding into first a junction box, then a combiner box, then ultimately to the inverter and on to .

Range hoods can either be hardwired or plugged in depending upon the unit. If your range hood had a plug when you bought it, then there’s no need for hardwiring it. On the contrary, the absence of a plug indicates that it needs to be hardwired. Range hoods that come with a plug can simply be plugged right into a . See moreFor range hoods that don’t come with a pre-installed plug, you’ll have to hardwire it. Hardwiring means that you’ll need to connect it to your house’s circuit manually. For this, you’ll need . See moreRange hoods do not require a dedicated circuit to function. Dedicated circuits only power a single outlet which means a single electronic appliance will operate at a time. These circuits . See moreAn electric stove and a range hood should not be on the same circuit. Electric stoves can draw up to 40 amps, whereas an exhaust hood barely crosses 7. Having the two of these appliances on the same circuit will most certainly cause an overload. If you do . See more

Range hoods do not draw more than 7 amps at best. For lighter units, you can expect around 2-4 amps. A 20-amp circuit breaker is suitable for a range hood. This way other smaller . See moreProper wiring is crucial when it comes to your kitchen range hood, as it ensures the safe and efficient operation of the appliance. The wiring connects the hood to the electrical system of .When it comes to installing an Ansul Hood System, proper wiring is essential for ensuring the safety and functionality of the system. In this step-by-step guide, we will walk you through the process of wiring your Ansul Hood System with .

The wiring diagram outlines the specific connections that need to be made between the kitchen range hood and the electrical system of the house. It provides details on the type of wires to use, the color coding of the wires, and . The gas solenoid is usually tied in with the hood control box. The exhaust must be on for the gas to flow. The hood control box usually has 2 .Determine the exact location of the hood – consult your project plans and drawings. The area should be inspected to verify that there are no interferences which will prevent proper .

wiring range hood circuit

In this article, we will guide you through the steps of wiring a range hood, from gathering the necessary tools and materials to making the electrical connections. Before you begin, it is important to familiarize yourself with the specific .Wiring a Range Hood. Many range hoods have discrete electrical junction boxes with knockouts into which you insert cable clamps and cables. In the example shown here, the shroud that encloses the duct doubles as a junction box. Run the electrical line from where it comes out of the range hood over into the electrical box. Strip the wires back with a wire stripper and pair white to white, black to black and copper ground to ground. Connect them with wire .

A range hood’s installation can be split into two parts. The first one consists of setting up the hood and venting it, while the other is the electrical work that powers up the unit. Both parts of the installation are equally important and .Proper wiring is crucial when it comes to your kitchen range hood, as it ensures the safe and efficient operation of the appliance. The wiring connects the hood to the electrical system of your home, providing power to the fan and lights while also adhering to .

electricity power saving box

When it comes to installing an Ansul Hood System, proper wiring is essential for ensuring the safety and functionality of the system. In this step-by-step guide, we will walk you through the process of wiring your Ansul Hood System with detailed instructions and a helpful diagram.The wiring diagram outlines the specific connections that need to be made between the kitchen range hood and the electrical system of the house. It provides details on the type of wires to use, the color coding of the wires, and the specific terminals or connectors to use for each connection. The gas solenoid is usually tied in with the hood control box. The exhaust must be on for the gas to flow. The hood control box usually has 2 contactors within it fresh air supply and exhaust.Determine the exact location of the hood – consult your project plans and drawings. The area should be inspected to verify that there are no interferences which will prevent proper installation. All overhead beams and angles must be structurally strong enough to .

In this article, we will guide you through the steps of wiring a range hood, from gathering the necessary tools and materials to making the electrical connections. Before you begin, it is important to familiarize yourself with the specific requirements of your range hood model.Wiring a Range Hood. Many range hoods have discrete electrical junction boxes with knockouts into which you insert cable clamps and cables. In the example shown here, the shroud that encloses the duct doubles as a junction box. Run the electrical line from where it comes out of the range hood over into the electrical box. Strip the wires back with a wire stripper and pair white to white, black to black and copper ground to ground. Connect them with wire connectors and then put .

Step-by-Step Wiring Instructions 1. Determine Hood Location. Use the stud finder to locate studs in your ceiling or wall where you plan to mount the hood. Mark the center of the hood and align it with the studs. 2. Install Electrical Box. Drill a hole in the ceiling or wall where the electrical box will be mounted. Insert the electrical box and .

A range hood’s installation can be split into two parts. The first one consists of setting up the hood and venting it, while the other is the electrical work that powers up the unit. Both parts of the installation are equally important and .Proper wiring is crucial when it comes to your kitchen range hood, as it ensures the safe and efficient operation of the appliance. The wiring connects the hood to the electrical system of your home, providing power to the fan and lights while also adhering to .When it comes to installing an Ansul Hood System, proper wiring is essential for ensuring the safety and functionality of the system. In this step-by-step guide, we will walk you through the process of wiring your Ansul Hood System with detailed instructions and a helpful diagram.The wiring diagram outlines the specific connections that need to be made between the kitchen range hood and the electrical system of the house. It provides details on the type of wires to use, the color coding of the wires, and the specific terminals or connectors to use for each connection.

The gas solenoid is usually tied in with the hood control box. The exhaust must be on for the gas to flow. The hood control box usually has 2 contactors within it fresh air supply and exhaust.Determine the exact location of the hood – consult your project plans and drawings. The area should be inspected to verify that there are no interferences which will prevent proper installation. All overhead beams and angles must be structurally strong enough to .

In this article, we will guide you through the steps of wiring a range hood, from gathering the necessary tools and materials to making the electrical connections. Before you begin, it is important to familiarize yourself with the specific requirements of your range hood model.Wiring a Range Hood. Many range hoods have discrete electrical junction boxes with knockouts into which you insert cable clamps and cables. In the example shown here, the shroud that encloses the duct doubles as a junction box.

Run the electrical line from where it comes out of the range hood over into the electrical box. Strip the wires back with a wire stripper and pair white to white, black to black and copper ground to ground. Connect them with wire connectors and then put .

range hood wiring instructions

electricity meter box key

electricity meter box location requirements qld

In this article, you will find the most common seven types of rivets for sheet metal assembly. Therefore, before choosing your next rivets for the assembly process, read this guide. 1. Solid Rivets. 2. Tubular Rivets. i. Full Tubular Rivets. ii. Semi-tubular Rivets. 3. Blind Rivets. 4. Flush Rivets. 5. Split Rivets. 6. Self-Piercing Rivets. 7.

electrical box hood system wiring|kitchen range hood wiring diagram