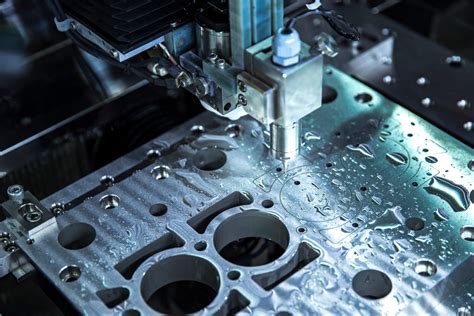

cnc production machining CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC . You can use mig welders as spot welders, just drill a small hole in the area to be spot welded then weld a spool in it.

0 · what is cnc in manufacturing

1 · how does cnc machine work

2 · cnc manufacturing technology

3 · cnc machining operations

4 · cnc machining manufacturing process

5 · cnc machining manufacturing

6 · cnc machining capabilities

7 · cnc machine fabrication

The term hardwired here means that an electric wire that powers the smoke detector runs directly into the electrical connection box. This is quite different from devices that are powered by plugging into the wall.

Production CNC machining process involves leveraging CNC technology to attain high-scale production of different metal and non-metal parts and components with tight tolerances, superior quality, higher dimensional . CNC machining is a "subtractive" manufacturing process that typically uses computerized controls and machine tools to remove layers of material from a blank (or workpiece) and produce a custom part.Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the .

CNC, or Computer Numerical Control, encompasses the manufacturing process where machines cut, carve and form parts based on computer codes that control the cutting .CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC . CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any .

In this post, we’ll explore three types of CNC production machining: low volume and high volume and prototype CNC machining. We’ll also discuss the benefits of each type of production and help you decide which type is the . CNC machining is a precise and efficient manufacturing process widely used to produce high-quality, precision parts. The process is automated and controlled by computer systems, which reduces the need for manual .

Production CNC machining process involves leveraging CNC technology to attain high-scale production of different metal and non-metal parts and components with tight tolerances, superior quality, higher dimensional accuracy, and reliability within production deadlines. CNC machining refers to the manufacturing and processing of parts and products controlled by computers. It involves the use of computer numerical control (CNC) machine tools to automatically remove excess material from a workpiece by processing and adjusting it.CNC machining is a "subtractive" manufacturing process that typically uses computerized controls and machine tools to remove layers of material from a blank (or workpiece) and produce a custom part.

what is cnc in manufacturing

Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the Protolabs Network's Engineering Guide . CNC, or Computer Numerical Control, encompasses the manufacturing process where machines cut, carve and form parts based on computer codes that control the cutting tool’s speed and movement. These machines cut metals, wood, foam, composites, plastics and more into precise parts with uses in almost every industry.CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding. CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

In this post, we’ll explore three types of CNC production machining: low volume and high volume and prototype CNC machining. We’ll also discuss the benefits of each type of production and help you decide which type is the best for your business. CNC machining is a precise and efficient manufacturing process widely used to produce high-quality, precision parts. The process is automated and controlled by computer systems, which reduces the need for manual labour and increases the consistency and repeatability of the finished product.

In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc. CNC machining services use a subtractive fabrication method.

Production CNC machining process involves leveraging CNC technology to attain high-scale production of different metal and non-metal parts and components with tight tolerances, superior quality, higher dimensional accuracy, and reliability within production deadlines. CNC machining refers to the manufacturing and processing of parts and products controlled by computers. It involves the use of computer numerical control (CNC) machine tools to automatically remove excess material from a workpiece by processing and adjusting it.CNC machining is a "subtractive" manufacturing process that typically uses computerized controls and machine tools to remove layers of material from a blank (or workpiece) and produce a custom part.

Learn all you need to know about CNC machining in 25 minutes or less. Whether you are an experienced design engineer or just getting started with CNC, this guide is for you. Short on time? Download for free the PDF version of the Protolabs Network's Engineering Guide . CNC, or Computer Numerical Control, encompasses the manufacturing process where machines cut, carve and form parts based on computer codes that control the cutting tool’s speed and movement. These machines cut metals, wood, foam, composites, plastics and more into precise parts with uses in almost every industry.

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding. CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

how does cnc machine work

In this post, we’ll explore three types of CNC production machining: low volume and high volume and prototype CNC machining. We’ll also discuss the benefits of each type of production and help you decide which type is the best for your business. CNC machining is a precise and efficient manufacturing process widely used to produce high-quality, precision parts. The process is automated and controlled by computer systems, which reduces the need for manual labour and increases the consistency and repeatability of the finished product.

sheet metal union hall brewster ny

sheet metal unlimited pl

These frames featured boxing under the engines and front suspensions to ensure a very rigid surface to mount to, and put increasing number of cross members in to improve rigidity, while still allowing frame flex to occur in the remaining portion of the frames, which were open C .

cnc production machining|cnc manufacturing technology