what is sheet metal processing Sheet metal fabrication is a versatile approach that begins with the selection of a flat metal sheet, typically steel, aluminum, or stainless steel, and transforms it into the desired component through various processes. By connecting sales, production, inventory, quality, and fulfillment data, ERP software solutions give metal companies real-time visibility and enhanced coordination across the business. This streamlines operations reduces costs through optimized processes, and allows faster adaptation to market shifts based on actionable insights.

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal process in manufacturing

4 · sheet metal fabrication techniques

5 · sheet metal diagram fabrication

6 · disadvantages of sheet metal

7 · basic sheet metal fabrication techniques

Laser welding is an advanced joining process that utilizes a highly focused, high-intensity laser beam to fuse metal surfaces. The process begins when the concentrated laser energy is directed onto the workpiece, typically .

Sheet metal fabrication is a versatile approach that begins with the selection of a flat metal sheet, typically steel, aluminum, or stainless steel, and transforms it into the desired component through various processes.The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In this article, we’ll explore the nine vital steps in sheet metal fabrication, providing valuable insights for businesses and industry professionals.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .

Sheet metal processing is a method that manipulates flat sheets of metal into desired shapes and structures. Understanding the sheet metal forming process gives us insights into the world of manufacturing, revealing the ingenious . Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to . Sheet metal fabrication is a set of manufacturing processes for turning sheet metal into functional parts. For this guide, we have divided the processes into three categories: cutting, deformation, and assembly.

What is sheet metal processing? Sheet metal processing are parts made by a comprehensive cold working process for thin metal plates (usually less than 6mm), including shearing, punching, cutting, bending, welding, riveting, .

It’s the process of transforming flat sheets of metal — like aluminum, steel or stainless steel — into desired shapes and forms. It involves a combination of cutting, bending, forming, and joining techniques to create .

Sheet metal processing is a broad concept that covers a large number of machining operations applied to metal sheets. It is often done on behalf of diverse industrial manufacturing companies, who then incorporate the processed sheet material into their own production lines. Sheet metal processing or sheet metal fabrication includes: folding, shearing, punching, welding, riveting, splicing and other processes. In general, the process of forming a sheet by hand or mechanical is called sheet metal .

What is Sheet Metal? Sheet metal is an industrial process that forms thin, flat pieces of metal, such as steel and tin, into coils. In the U.S., the thickness of sheet metal is typically specified by its gauge, which ranges from 30 gauge to about 7 gauge. Post-processing and surface finishing techniques in sheet metal fabrication significantly enhance the final properties and aesthetics of sheet metal products. After the initial formation of sheet metal parts, several supplementary operations ensure they meet desired specifications and appearance . Sheet metal fabrication is a process that involves the creation of objects from thin sheets of metal. It can involve everything from simple shapes to more complex designs. In this article, we will discuss what sheet metal fabrication is, and provide a guide on how to design and manufacture products using this process. Discover what metal shearing is and how it prepares sheet metal for fabrication. Learn about its applications, benefits, and the technology behind it. . The clean cuts shearing produces help make assembly and further processing of the metal components easier. Versatility: Regardless of the type of metal you’re working with, shearing can .

various sheet metal processes

Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000. Ends 30 Nov 2024. . but it can also create longer processing times. For example, a laser cutter cannot make tiny holes, so a .

types of sheet metal process

Sheet metal stamping is a fabrication process that uses dies, punches, and other tools to bend, cut, punch, flange, or otherwise shape the sheet metal into the end component. . — Secondary processing available; If you require parts manufactured in large numbers, you may benefit from sheet metal stamping over metal fabrication. However, you .Sheet metal processing covers the entire process from design to finished product, involving many key links such as material selection, process determination, and precision control. This article will deeply explore the common process types and significant advantages of sheet metal processing, helping users make more informed choices when . Sheet metal processing also facilitates the assembly of prefabricated metal components quickly and easily on site, which can shorten construction times and save costs. ConclusionSheet Metal Processing is a manufacturing methods with long history. This enables to produce accurate, intricate and lightweight components which can be used in several . Sheet metal parts are sheet metal parts, that is, parts that can be processed by means of stamping, bending, stretching, etc. A general definition parts with constant thickness during the processing. Generally, the three most important steps in a sheet metal factory are cutting, punching/cutting, and folding.

Sheet metal processing is a cold processing process for metal sheets (usually under 6mm), including cutting, punching, bending, welding, riveting, mold forming, and surface treatment. The character of it is that the thickness of the part is the same everywhere.

Sheet metal processing; United States | EN. Contact To MyTRUMPF Sheet metal processing Flexible tool concepts for flexible sheet metal processing. TRUMPF mainly focuses on machine tools for flexible sheet and tube processing. In addition to systems for bending, punching, and for combined punch laser processes, we offer systems for laser cutting . Sheet metal nibbling process. Nibbling is a sheet metal cutting technique that involves removing material incrementally. Nibbling allows for intricate patterns, curves, and shapes by creating overlapping holes or notches. Instead of cutting through the material in one go, nibbling makes multiple, small, and controlled cuts to achieve the .

To achieve the required sheet metal tolerance in sheet metal part design guidelines, manufacturers must use precise machinery during production. ADH has 20 years of experience in world of sheet metal manufacturing .

Sheet metal design options are very flexible. Clients can express a need for certain functionality and sheet metal materials leave room for many different solutions. Single prototypes to volume production are possible. . Sheet metal processing technology is not limited by material characteristics, whether it is high hardness aluminum alloy plate, carbide, or strange shape pipe, etc., can be directly cut and no deformation, processing flexibility is good, can process all kinds of graphics . Types of sheet metal processing. Sheet metal processing can be roughly divided into two types: manual sheet metal processing, which is performed manually, and machine sheet metal processing, which uses processing machines such as press machines. In the processing process, “hand sheet metal” is processed only by the power of the worker using tools such as .

Finishing and Post-Processing After stamping, these professionals may apply additional post-processing steps, such as deburring (removing sharp edges), cleaning, surface treatment, and coating, to enhance the appearance, durability, and functionality of the stamped parts.. By following this systematic approach, the stamping process transforms raw metal sheets or coils .Maximum precision levels are required whenever metal is being used. We automate your processes together in conjunction with you so that you can achieve your level of quality, productivity objectives, and create financially viable processes,. Integrated complete solutions create a revolutionary quality for thick sheet and thin sheet metal processing. Our own .

shiny metallic fabric

Guide to Sheet Metal: Applications, Industries, and CNC Processing What is Sheet Metal? Sheet metal is a thin, flat piece of metal formed by industrial processes and is one of the fundamental forms used in metalworking. It can be cut, bent, and shaped into various forms and is commonly used across multiple industries.

shimano handlebar junction box

A sheet metal shearing machine is a machine used in metal fabrication industry for cutting metal plates into various desired shapes and sizes. . ADH is a reputable sheet metal processing machine manufacturer with 20 years of experience. The quality and performance of their press brake, plate shearing machine, . Food Processing: Tanks, conveyors, storage containers, and processing machinery are just a few examples of food processing equipment manufactured using stainless steel sheet metal. This material is chosen for its hygiene and resistance to corrosion in food contact environments.

Bine ați venit Sheet Metal Processing Precizie. Calitate. Flexibilitate Contactați-ne Suntem gata să începem treaba Partenerul tău de încredere Calitate de la proiectare la produs finit Contactați-ne Adevărații specialiști sunt aici Un deceniu de experiență Acum, susținută de tehnologie ultramodernă Contactați-neMetal processing is the base of metal production, each metal manufacturing method includes some form of metal processing operations, which usually reshapes a metal blank or material into a part with specific geometry or dimensions.

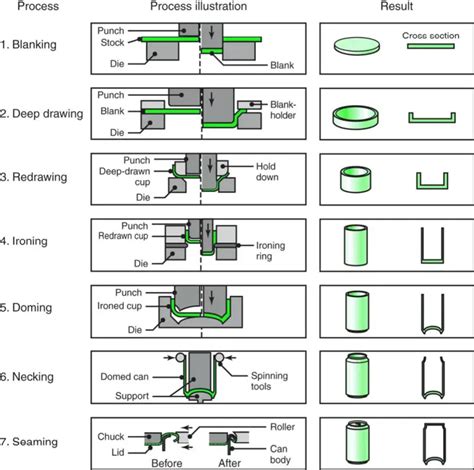

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking OperationsSheet metal processing refers to the manufacturing process of transforming sheet metal into functional components for other applications. Sheet metal typically refers to sheets of metal materials, including copper, zinc, aluminum, and stainless steel.

types of sheet metal fabrication

Forming converts flat sheet metal into 3-D parts by applying force without adding or removing material. The force must be great enough to change the metal's initial shape. Forming can . See more

what is sheet metal processing|disadvantages of sheet metal