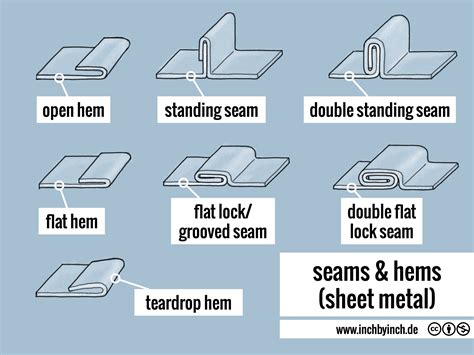

different sheet metal joints Forming a lap joint involves overlapping two edges in a specific manner. A plain lap jointrequires no fabrication and can be as simple as two edges offset simply by their thickness and some length along the edge. In like manner, a flush lap joint involves offsetting one edge to slide under the other piece of material, . See more Find a variety of vintage and antique storage cabinets on 1stDibs, including unique Art Deco storage cabinets, chinoiserie cabinets and more. Shop our used stainless steel kitchen .

0 · types of sheet metal seams

1 · sheet metal overlap joint

2 · sheet metal joints pdf

3 · sheet metal joints and seams

4 · sheet metal clinching joint

5 · interlocking sheet metal joints

6 · different types of metal joints

7 · different joining methods for metal

We have a wide selection of used filing cabinets and are always adding more to the inventory. Come into the showroom to find the perfect filing cabinet. The inventory includes fireproof, lateral, and vertical filing cabinets, in addition to custom storage towers.

types of sheet metal seams

Forming a lap joint involves overlapping two edges in a specific manner. A plain lap jointrequires no fabrication and can be as simple as two edges offset simply by their thickness and some length along the edge. In like manner, a flush lap joint involves offsetting one edge to slide under the other piece of material, . See moreAnother common type of sheet metal joint is the standing seam, which requires the forming of both edges. Firstly, bend the edge of the first piece at a 90-degree angle into a flange. . See moreAnother type of sheet metal joint is the grooved seam. As seen in the illustration, this joint is a curious combination of a flush lap and open hems. . See more

Finally, the double corner seamis some kind of mix between a corner seam and a grooved seam. Constructed with two open seams like a grooved . See more

The raw and flange corner jointis a type of sheet metal joint that closely resembles a plain lap joint and involves a flat stock piece joined to a 90-degree bend to form the corner. To join . See more

There are numerous types of edges, joints, seams, and notches used to join sheet-metal work. We will discuss those that are most often used. Edges are formed to enhance the appearance . How can we ensure secure and durable connections in sheet metal fabrication? This article explores various joining and fastening techniques, including TOX riveting, welding, and nail riveting. You’ll discover the pros and . What are the different Sheet Metal Joints? The various joints in metal sheets are lap joint, Seam Joint, standing seam joint, grooved seam joint, corner joint, and double corner seam joint. How are sheet metals joined .

Some common design choices for sheet metal joints are based on usage and seam characteristics. Things like material, pressure, thickness, and application come into the design consideration. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. Lap Joints (Plain and Flush)

Sheet metal joining operation is crucial part of the sheet metal fabrication process. Joint reliability depends on its type, sheet metal material, and manufacturing process. This article covers various types of sheet metal joining techniques, their advantages, disadvantages, and applications. Sheet metal joining refers to the process of connecting different sheet metal parts through specific techniques during sheet metal fabrication, aiming to achieve the functionality and performance of the overall structure.

There are numerous types of edges, joints, seams, and notches used to join sheet-metal work. We will discuss those that are most often used. Edges are formed to enhance the appearance of the work, to strengthen the piece, and to eliminate the cutting hazard of the raw edge. Discover the 7 most common sheet metal joint techniques that include riveted, welded, and adhesive joint types for appropriate enhancement of structural rigidity and effectiveness in your projects. How can we ensure secure and durable connections in sheet metal fabrication? This article explores various joining and fastening techniques, including TOX riveting, welding, and nail riveting. You’ll discover the pros and cons of each method, practical applications, and how they contribute to the strength and integrity of metal structures. What are the different Sheet Metal Joints? The various joints in metal sheets are lap joint, Seam Joint, standing seam joint, grooved seam joint, corner joint, and double corner seam joint. How are sheet metals joined together?

There are five major welding joint types: butt joint, tee joint, corner joint, lap joint and edge joint. Butt joints are the most common and can be made in various ways depending on factors like groove shape and width. Tee joints are formed when two pieces intersect at a 90° angle and can be created using different welding styles.There are a range of different welding techniques that can be used to join sheet metals, such as MIG and TIG welding, laser welding or friction stir welding, which is good for quickly joining sheets that are long or wide.

sheet metal overlap joint

Sheet metal welding is a crucial fabrication process because it is one of the simplest ways to join cut-out pieces of metal sheets to create the desired shape. In Sheet metal welding, the mating surfaces are subjected to intense heat to fuse them by melting the metal in a designated area.Some common design choices for sheet metal joints are based on usage and seam characteristics. Things like material, pressure, thickness, and application come into the design consideration. Today we will look at 5 common types of fabricated sheet metal joints that are extremely common across the industry. Lap Joints (Plain and Flush)Sheet metal joining operation is crucial part of the sheet metal fabrication process. Joint reliability depends on its type, sheet metal material, and manufacturing process. This article covers various types of sheet metal joining techniques, their advantages, disadvantages, and applications. Sheet metal joining refers to the process of connecting different sheet metal parts through specific techniques during sheet metal fabrication, aiming to achieve the functionality and performance of the overall structure.

There are numerous types of edges, joints, seams, and notches used to join sheet-metal work. We will discuss those that are most often used. Edges are formed to enhance the appearance of the work, to strengthen the piece, and to eliminate the cutting hazard of the raw edge.

Discover the 7 most common sheet metal joint techniques that include riveted, welded, and adhesive joint types for appropriate enhancement of structural rigidity and effectiveness in your projects. How can we ensure secure and durable connections in sheet metal fabrication? This article explores various joining and fastening techniques, including TOX riveting, welding, and nail riveting. You’ll discover the pros and cons of each method, practical applications, and how they contribute to the strength and integrity of metal structures. What are the different Sheet Metal Joints? The various joints in metal sheets are lap joint, Seam Joint, standing seam joint, grooved seam joint, corner joint, and double corner seam joint. How are sheet metals joined together? There are five major welding joint types: butt joint, tee joint, corner joint, lap joint and edge joint. Butt joints are the most common and can be made in various ways depending on factors like groove shape and width. Tee joints are formed when two pieces intersect at a 90° angle and can be created using different welding styles.

There are a range of different welding techniques that can be used to join sheet metals, such as MIG and TIG welding, laser welding or friction stir welding, which is good for quickly joining sheets that are long or wide.

Assuming adequate volume for the number of conductors, is it permissible to use an existing outlet box as a splice point for another circuit?

different sheet metal joints|sheet metal overlap joint