sheet metal die design The press brake contains an upper tool called the punch and lower tool called the die between which the sheet metal is placed. . Importance of the K-factor in sheet metal design. The K-factor is used to calculate flat patterns because it is .

Ford does refer to it as the Smart Junction Box in the TSB and in the Ford Service Manual Wiring Diagrams.

0 · types of sheet metal dies

1 · sheet metal stamping process pdf

2 · sheet metal stamping guidelines

3 · sheet metal stamping design guidelines

4 · sheet metal stamping basics

5 · sheet metal hole stamping tool

6 · sheet metal die design pdf

7 · metal stamping process flow chart

A "Gem" box is another word for a sectional metal device box, or most commonly referred to as an old work box. You know, the kind you install with "madison straps." They were also commonly used for new work for many decades until the advent of the far superior Carlon non-metallic boxes.:thumbup:Like standard rectangular boxes, gangable electrical boxes hold household switches and electrical outlets. Still, they are oversized so that two, three, or four devices can be mounted side-by-side. Gangable electrical boxes are often made of durable galvanized steel.

What is stamping? Stamping, also known as pressing, is a manufacturing process where flat sheet metal or non-metallic materials are formed into specific shapes using specialized tools and equipment. This process typically occurs at room temperature, distinguishing it as a cold-forming technique. The definition of . See moreBasic requirements for stamping on sheets 1. Meet performance requirements 2. Meet the requirements of the stamping process Satisfying the performance requirements is the first, and meets the stamping process requirements as much as possible while meeting the . See moreSelection principle of stamping equipment: 1. The nature of the stamping process: separation or molding process 2. The press force: open, . See more

For a slot or hole > 1" diameter then the minimum distance "D" = 2.5T + R (see fig. "C") Form height to thickness ratio – To determine the minimum form height for sheet metal use the .

Vukota Boljanovic, Ph.D., has nearly 50 years of experience in applied engineering in the aircraft and automotive industries, as well as academia.He has performed extensive research in manufacturing engineering, .The press brake contains an upper tool called the punch and lower tool called the die between which the sheet metal is placed. . Importance of the K-factor in sheet metal design. The K-factor is used to calculate flat patterns because it is .Download PDF - Sheet Metal Forming Processes And Die Design [PDF] [ce6pah57mpo0]. By an engineer with decades of practical manufacturing experience, this book is a complete modern guide to sheet metal f.

PRODUCT DESIGN FOR SHEET METAL STAMPING - 16 HOURS . This advanced, practical course focuses on understanding the key principles needed to process and design deep-drawing and stretching dies. It is intended for experienced sheet metal process engineers, tool designers and die makers. COURSE TOPICS: Blanking tool Design in NX (Tool and Die Making)In This tutorial We'll discuss on Complete Blanking Die Designing🟢 For advance Offline & Online Corporate Tr.Sheet Metal Stamping Stamping presses and stamping dies are tools used to produce high volume sheet metal parts. The press provides the force to close the stamping dies where they shape and cut the sheet metal into finished parts. Production stamping is generally performed using sheet metal materials .020” to .080” thick, but the processFinally, in a single volume, a reference that presents engineering-level information on press-working sheet metal, die design, and die manufacturing! Concentrating on simple, practical methods, this book will be an invaluable resource for anyone looking for detailed information about die design and the manufacture of stamping dies, particularly .

Sheet Metal Forming Processes and Die Design; View Inside. Sheet Metal Forming Processes and Die Design. by Vukota Boljanovic. Second Edition. 320 Pages, 8.00 x 10.00 x 1.00 in. Paperback; ISBN: 9780831134921; Availability: In Stock; Publication Date: April 2014; .95. BUY Digital Edition Go to eBook; EDUCATORS:

types of sheet metal dies

When selecting metal sheet blanking clearances, according to the technical requirements of the blanking parts, the use characteristics and specific production conditions, etc., first determine the type of clearance to be adopted according to Table 3-19, and then select this type gap value accordingly according to Table 3-20. . When blanking . An automobile consists of 350–400 sheet metal parts and about 1,250 molds are needed for their production. The total size of the publication data for a sheet metal die design can be 4 GB. During the production process, at least 5 revisions of this data are created and each revision is stored.

subcontract metal fabrication services

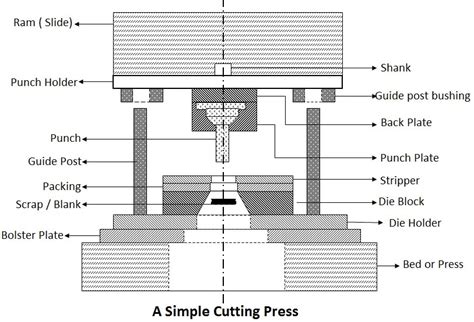

2. CUTTING ACTION IN A DIE The cutting action of sheet metal in press work is a shearing process. Blanking and piercing operations are performed to prepare stock for further processing. The punch is of same shape as of die opening except that it is smaller on each side by an amount known as clearance. as the punch touches the material and travels downwards, .Die Design Part-2Sheet metal product design AUTOMATION OF SHEET METAL COMB INATION DIE DESIGN PROCESS . Hussein M.A. Hussein 1, H ossam Salem 1, W alla Abdelzaher 1, V ishal Naranje 2, Morcos I. Ghobrial 1, Azza Barakat 1 .

The result: affordable and user-friendly incremental forming-simulation software running inside of parametric die-design software. “The forming-simulation software no longer is disconnected from the die-design .dvb DESIGN + ENGINEERING is India’s premier manufacturer of Progressive Dies and Sheet Metal Stamping Dies. Our experience and expertise in building dies for long term overseas partners uniquely positions us to offer world class, .!“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight . Examples-sheet metal formed . Female die Male die (punch/post) Metal sheet Blank holder (ring) on cushion Compressible cushion Sheet metal stamping/drawing – car industry •90million cars and commercial vehicles

sheet metal stamping process pdf

Addeddate 2022-01-07 05:36:34 Identifier sheet-metal-forming-processes-and-die-design Identifier-ark ark:/13960/s2gqstq6128 Ocr Check out the newest offerings to help ease die design and build, and ensure that tooling performs as planned in the press, producing the right part features hit after hit. . the Dynaform 6.0 die system simulation software enables users to quickly conduct sheet metal stamping simulations to estimate the blank cost and formability of stamping .

Creating a die for a sheet metal drawing project is a meticulous process that requires a thorough understanding of the material’s properties, the die design, and the manufacturing process. The choice of method for making the die is primarily dictated by your project’s requirements, including the die design’s complexity, the required .Find many great new & used options and get the best deals for Sheet Metal Stamping Dies : Die Design and Die-Making Practice by Vukota Boljanovic (2012, Trade Paperback) at the best online prices at eBay! Free shipping for many products!

Boljanovic, Vukota Sheet Metal Forming Processes And Die Design Industrial Press, Inc ( 2004) Bookreader Item Preview remove-circle Share or Embed This Item. Share to Twitter. Share to Facebook. Share to Reddit. Share to Tumblr. Share to Pinterest . BRASS, METAL, TOOL, ELECTRICAL DISCHARGE, MACHINISTS, MILLING MACHINES, .

A sheet metal stamping die is a custom precision tool that cuts, pierces or forms sheet metal into a profile or shape. The die's cutting and forming sections typically are made from tool steel. Custom metal stamping dies are commonly used in hydraulic, mechanical, pneumatic, and air over oil punch presses to produce the metal stamped components . Enhance your metal stamping and die design skills with our comprehensive guide on deep drawing. Learn the process, techniques, and tips for successful metal forming. . My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am .

1 Die Design Dies/ Presses Part1-Types & Components Tool Design, MET3331 Dr Simin Nasseri Southern Polytechnic State University . bend, or form sheet metal. 4. 4 Dies & Presses Compound die: A die designed to simultaneously perform more than one operation with each stroke of the press. For example, a compound die may blank and pierce in a .Die Design is a comprehensive solution for quality die design, supporting associativity with the part design at every stage of die development and including a variety of functions specific to automotive progres-sive dies. Tooling process expertise Part preparation. Efficiently design both straight break and freeform sheet metal parts using a .

As the bender moves down, the rocker makes contact with the sheet metal. One contact point acts as a holding pad, while the opposite contact point rotates, creating the bending action. After the bend is completed and on the press's returnstroke, the spring forces the rocker to return back to its original or idle position ( Figure 1 ).

sheet metal stamping guidelines

sturdi steel press box

sublimation blank box metal tin

Features metal drop-in unitized seat box for strength and durability. All metal construction to the floor for strength and durability.

sheet metal die design|types of sheet metal dies