cnc 5th axis part Self-Centering Vises: Experience top-tier clamping force and precision with 5th .

In this video I show you how to install an "old work" electrical box. I install this in a kitchen cabinet but the process is similar for other applications. I also discuss how "old work" and.

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · 5th axis workholding system

4 · 5th axis workholding price list

5 · 5th axis cnc workholding

6 · 5 axis cnc price

7 · 5 axis cnc explained

Sheet metal industry in a nutshell: The Tin Knocker-A typical 9-5, clock punching drunk or drug addict (or both) that shows up late every other day with a hand bag full of bull shit tools.

5 Axis CNC machine products by 5thAxis to enhance your machine productivity. Explore a comprehensive range of workholding solutions.

All Products - 5 Axis CNC Machine and Products - 5thAxis

Sale - 5 Axis CNC Machine and Products - 5thAxis

Unlock Automation Potential: 5th Axis offers robot-compatible tooling, including .

Top Tooling - 5 Axis CNC Machine and Products - 5thAxis

Self-Centering Vises: Experience top-tier clamping force and precision with 5th .Double Station 3-Axis Vises: Say goodbye to clunky and oversized workholding .Dovetail Fixtures: Unleash unparalleled rigidity in a compact form factor with 5th .5 Axis CNC machine products by 5thAxis to enhance your machine productivity. Explore a comprehensive range of workholding solutions.

Full 5-axis CNC machining means a machine’s processing ability to move a tool or a workpiece in five different axes simultaneously. 5-axis CNC machining is considered a more evolved and sophisticated version of the CNC machining process.FANUC 5 axis CNC machining solutions are the most reliable 5th axis CNCs in the industry, including solutions for 5 axis CNC mill, 5 axis CNC machine & more.5-Axis is best known for its ability to create complex parts, such as turbine blades, propellers, or orthopedic and knee implants. Before 5-axis, these parts were achieved by adding on fixtures or steps in the setup process. If your shop is currently using additional setups on your VMCs, you’re a strong candidate for a 5-axis machine.

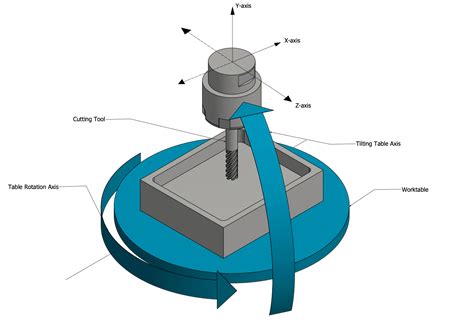

5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, accuracy, speed, and production efficiency. Learn CAD, CAM, & CNC:https://titansofcnc.comSubscribe to our podcast channel:@titansofcncpodcast https://www.facebook.com/titansofcnchttps://www.instagram.. Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle .5-axis machining is easier and less expensive than you think, and can dramatically increase your profits. This versatile 5-axis universal machining center can position parts to nearly any angle for 5-sided (3+2) machining, or provide simultaneous .

At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three primary directions: up and down, left and right, and forward and backward.

electrical enclosure material regulations

5-axis CNC machining involves simultaneous movement along five axes—three linear (X, Y, Z) and two rotational. This capability allows for the creation of complex parts in a single setup, significantly enhancing precision and efficiency.

5 Axis CNC machine products by 5thAxis to enhance your machine productivity. Explore a comprehensive range of workholding solutions. Full 5-axis CNC machining means a machine’s processing ability to move a tool or a workpiece in five different axes simultaneously. 5-axis CNC machining is considered a more evolved and sophisticated version of the CNC machining process.

what is 5 axis milling

FANUC 5 axis CNC machining solutions are the most reliable 5th axis CNCs in the industry, including solutions for 5 axis CNC mill, 5 axis CNC machine & more.5-Axis is best known for its ability to create complex parts, such as turbine blades, propellers, or orthopedic and knee implants. Before 5-axis, these parts were achieved by adding on fixtures or steps in the setup process. If your shop is currently using additional setups on your VMCs, you’re a strong candidate for a 5-axis machine. 5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, accuracy, speed, and production efficiency.

Learn CAD, CAM, & CNC:https://titansofcnc.comSubscribe to our podcast channel:@titansofcncpodcast https://www.facebook.com/titansofcnchttps://www.instagram.. Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle .5-axis machining is easier and less expensive than you think, and can dramatically increase your profits. This versatile 5-axis universal machining center can position parts to nearly any angle for 5-sided (3+2) machining, or provide simultaneous . At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three primary directions: up and down, left and right, and forward and backward.

what does 5 axis mean

small 5 axis cnc mill

The truck bed and tailgate are used for hauling cargo, and all kinds of customization options allow for different needs. Front Bumper: Role in safety and aesthetics. Grille: Airflow and cooling system components.

cnc 5th axis part|5th axis cnc workholding