semi piercing in sheet metal Piercing does not remove any material from the sheet of metal. Instead, it only displaces metal, creating an opening that causes slight deformation around the edge of the hole. Punching and blanking both involve .

$23.99

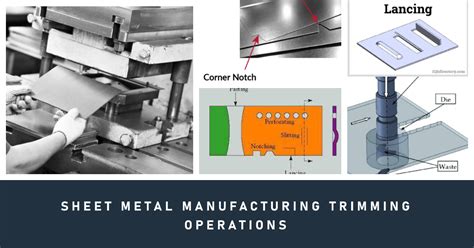

0 · trimming operation in sheet metal

1 · sheet metal blanking process

2 · shearing process in sheet metal

3 · punching operation in sheet metal

4 · piercing process in sheet metal

5 · perforating operation in sheet metal

6 · lancing operation in sheet metal

7 · blanking operation in sheet metal

Carlon produces a full line of weatherproof electrical products for safe installation and operation in wet or damp locations. The line includes In-Use Weatherproof Covers and moisture sealed Lighting Fixtures, all NEMA 3R rated and UL-listed.

trimming operation in sheet metal

Punching blanking and piercing are sheet metal shearing operations to modify existing blank. Similar machines but different punch and .Blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. Blanking produces the outside features of the component, while piercing produces internal holes or shapes. The web is created after multiple components have been produced and is considered scrap material. The "slugs" produced by piercing internal features are also consider. Strictly speaking, there are three types of shearing operations in sheet-metal forming practice: (a) open shearing, (b) blanking, and (c) piercing. Open shearing (also called .It focuses on blanking and piercing operations in a press tool to form and shape the final part geometry. The types of piercing operations include conventional piercing, piercing with a pointed punch, piece-and-extrude operations, slotting, .

Metal stamping is a complex process that can include a number of metal forming processes — blanking, punching, bending, and piercing, to name a few. All of these processes come with . Piercing does not remove any material from the sheet of metal. Instead, it only displaces metal, creating an opening that causes slight deformation around the edge of the hole. Punching and blanking both involve .

metal thing at the top of house

Sheet Metal Shearing, Blanking, Punching, Piercing, etc. Sheet metal fabrication processes involve a variety of methods and tools to cut thin metal sheets (< 6 mm thick) in order to achieve smaller, desirable pieces. Blanking and piercing are manufacturing processes by which certain geometrical shapes are sheared off a sheet metal. If the sheared off part is the one required, the processes referred to as.The article discusses the presses and tools used in piercing. It illustrates the use of compound dies, progressive dies, and transfer dies; piercing of thick and thin stock and piercing holes at .EZ RIVET: This sturdy, metalworking tool pierces metal and sets semi-tubular rivets and eyelets. Many jewelry makers use riveting as a cold forging process. . Utilizing this tool is a breeze – position your metal blank or sheet metal .

Piercing Holes Edge-to-Hole clearance Forming-Bend Relief Edge Bulging Hole-to-form Slot-to-form Drawing shapes Drawing Radii - 2 - Forming Basics . Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. - 3 - It discusses various sheet metal forming processes like blanking, piercing, bending, deep drawing and provides examples of different press tools. . Semi-Piercing : It is done to create a projection of a lug on the face of a .

Blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. Blanking produces the outside features of the component, while piercing produces internal holes or shapes. . This allows for complex shapes to be formed in sheet metal up to 6 mm (0.25 in) thick using simple tools. . Rivets are fasteners that are used to connect parts in sheet metal assembly. In this article, you will find the most common seven types of rivets for sheet metal assembly. Therefore, before choosing your next rivets for the assembly process, read this guide. 1. Solid Rivets You can use them [.]Piercing of all the holes is best done together to ensure good hole-to-hole tolerance and part repeatability. However if the material distorts, the method described below can be done. When there are large numbers of holes, in a tight pitch, there could be distortions, due to the high amount of tension on the upper surface due to stretching and .Semi Tubular self-piercing rivets can be used with materials such as leather, some plastics, and light sheet metals. When piercing sheet metal, adjustments may be suggested to the rivet raw material, hole diameter and heat treatment. Self- piercing rivets can be used especially in difficult spot welding applications, piercing and fastening in .

Blanking. The term blanking can be somewhat confusing, because it has more than one definition. The blank is defined as the flat piece of sheet metal that eventually turns into the finished piece part.. Blanking is a method in which the sheet metal is cut and the slug is saved for further pressworking. The size and the shape of the blank are proportional to the size and .

This document discusses sheet metal cutting operations. It describes the cutting mechanism as a shearing action between sharp cutting edges of a punch and die. . • Semi notching removes a portion of a metal from the interior of the sheet. 18. Trimming • Trimming is a cutting operation performed on a formed part to remove excess metal and .

This procedure is likely used for the further processing of semi-finished products made of sheet metal, partially-finished parts in the automobile industry or plastic parts in the white goods industry. . The required die clearance depends on the shear strength and the thickness of the sheet. In the TOX®-Piercing Systems brochure, a table .Set sheet metal grommets quickly and efficiently with Micron’s industrial die sets. These dies do the same job as a 4 piece set by combining features from the cutter and setting dies. The die first punches the hole in the material on the first pass, then sets the grommet on the second pass. This eliminates the need to swap dies or run concurrent machines. √ The top shaft of our dies is 1/4 .This procedure is likely used for the further processing of semi-finished products made of sheet metal, partially-finished parts in the automobile industry or plastic parts in the white goods industry. . The required die clearance depends on the shear strength and the thickness of the sheet. In the TOX®-Piercing Systems brochure, a table .

sheet metal blanking process

Set sheet metal grommets quickly and efficiently with Micron’s industrial die sets. These dies do the same job as a 4 piece set by combining features from the cutter and setting dies. The die first punches the hole in the material on the first pass, then sets the grommet on the second pass. This eliminates the need to swap dies or run concurrent machines. √ The top shaft of our dies is 1/4 .Get free shipping on qualified Self Piercing Screws products or Buy Online Pick Up in Store today in the Hardware Department. . Sheet Metal Screws / Self Piercing Screws. Self Piercing Screws. Screw Length: 1 in. Screw Length: 1/2 in. Screw Length: 3/4 in. Everbilt. Malco. Teks. Shop Savings. 50 Results. Filters.

Set sheet metal grommets quickly and efficiently with Micron’s industrial die sets. These dies do the same job as a 4 piece set by combining features from the cutter and setting dies. The die first punches the hole in the material on the first pass, then sets the grommet on the second pass. This eliminates the need to swap dies or run concurrent machines. √ The top shaft of our dies is 1/4 .NOTE. 1) Please indicate the dimension of A or B, when you order.(You can also have both dimension A and B) 2) The height(H) is preferably less than 60% of the material thickness. In addition, unless otherwise instructed us is .Creating a hole in paper using a pen or any sharp tool is also known as piercing. The piercing operation for sheet metal is also similar. For this operation, a blanking punch is used. . And in semi notching operation metal cutting out . 1. Selection of Sheet Metal Materials. Sheet metal materials are the most commonly used materials in the structural design of communication products. Understanding the comprehensive performance of materials and the correct material selection have an important impact on product cost, product performance, product quality, and processability.. Selection .

Set sheet metal grommets quickly and efficiently with Micron’s industrial die sets. These dies do the same job as a 4 piece set by combining features from the cutter and setting dies. The die first punches the hole in the material on the first pass, then sets the grommet on the second pass. This eliminates the need to swap dies or run concurrent machines. √ The top shaft of our dies is 1/4 .Rolled Rim Grommet Dies With Hole Piercing; Sheet Metal Grommet Dies With Hole Piercing Dies; Self Piercing Grommet-Paper Eyelet and Plastic Grommet Dies. Paper Eyelet Dies; Plastic Grommet Dies . MC-20 Single Cylinder Semi-Heavy Duty Pneumatic Fastening Attaching Machine $ 1,950.00 – $ 2,156.90. Shipping to be determined per weight .

A semi-tubular self-piercing rivet having a rivet head and a rivet shaft, the shaft bore of which satisfies the following relationship in relation to the length of the semi-tubular self-piercing rivet: 0.4 ≤ T B L N ≤ 0.6 , the total length of the self-piercing rivet L N being ≤4 mm.

Int J Adv Manuf Technol (2008) 36:658–670 DOI 10.1007/s00170-006-0873-z ORIGINAL PAPER Sheet metal cutting and piercing operations planning and tools configuration by an expert system T. Giannakakis & G. C. Vosniakos Received: 22 September 2006 / Accepted: 7 November 2006 / Published online: 4 January 2007 # Springer-Verlag London Limited 2006 Abstract This paper .The diameter of the semi-circular sheet is 28 cm. ∴ The radius of the semi-circular sheet (r) = 28 2 = 14 c m. Since the semi-circular sheet is bent to form an open conical cup. Thus, the slant height of a conical cup (l) is equal to the radius of semicircular sheet (r). ∴ l = r = 14 cm

Sheet metal fabrication design guide with tips and best practices on designing sheet metal parts for processing via laser cutting and precision CNC bending. Search Now. Popular search terms. . Between semi-pierced hole and a bend: .The PL-20 machine is a semi-automated device designed to feed grommets automatically and features a side chute for washers to slide down and align with the bottom die. This side chute is compatible exclusively with sizes #1, #2, and #3. . Self-Piercing Grommet Dies; Sheet Metal Grommet Dies With Hole Piercing Dies; Snap Dies; Tubular Rivet . Piercing Sheet Metal Formula Thread starter richg1; Start date Oct 15, 2004; Status Not open for further replies. Oct 15, 2004 #1 richg1 Mechanical. Sep 25, 2002 77 AU. Hi all, Does anyone know of, or have a calculation to estimate the force required to pierce sheet metal, either with a conical point, or a tapered knife edge?

shearing process in sheet metal

Sheet Metal Forming Processes 8.1 Classification Inthischapter, abriefoutlineof various sheet metal formingprocesses isdescribed, . and Piercing When the punch and the die surfaces are exactly flat and at 90° to the motion of the punch, the cutting force is determined by the following formula: load on the press (in N), F

punching operation in sheet metal

$26.96

semi piercing in sheet metal|sheet metal blanking process