sampling metal fabrication quality What steps do you take to ensure high-quality work? Sample answer: Quality is paramount in my work. I always double-check all measurements and drafts before beginning the fabrication process. I also conduct routine inspections during the fabrication process to ensure the final product meets the required standards. CNC Lathes / Turning Centers; CNC Vertical Machining Centers; CNC Horizontal Machining Center; CNC Multi Axis Machining Center; USED CNC MACHINES. CNC Boring Mill; CNC .

0 · tolerances in metal manufacturing

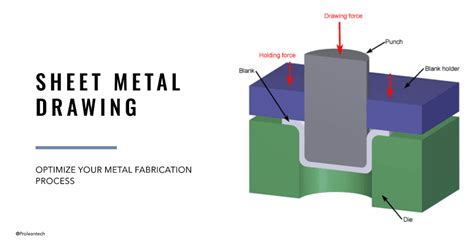

1 · sheet metal drawing quality

2 · quality metric for sheet metal

3 · quality control in metal manufacturing

4 · metal parts quality control pdf

I'm running 2-2-2-4 URD 155A Aluminum cable from my house to a subpanel in a shed and must splice it outside the house in a junction box to 1/0-1/0-1/0-4 Copper THHN .

To maintain quality in sheet metal fabrication drawings, implement version control to track changes and keep an audit trail. Use automated error .

Download a Fabrication Quality Plan Sample, and see what you'll get in each section of your welding quality control plan template. Or, contact us at 410-451-8006 and we'll answer all of your questions. See why hundreds of companies .

Quality System currently in practice at Medford Fabrication. This manual is intended to be in compliance with ANSI/ASQC Standard Q9002 – 1994, Quality System – Model for Quality Assurance in Production and Installation. The distribution of this manual is controlled through the Quality Manager. Quality control in steel fabrication involves a range of techniques and tools to ensure the final product's quality, safety, and efficiency. Some of the key QC techniques used in steel fabrication include: Non-destructive testing . What steps do you take to ensure high-quality work? Sample answer: Quality is paramount in my work. I always double-check all measurements and drafts before beginning the fabrication process. I also conduct routine inspections during the fabrication process to ensure the final product meets the required standards.Quality control metal fabrication jobs. Sort by: relevance - date. 5,000+ jobs. Quality Manager. Metal Technologies 2.9. Hillsdale, MI 49242. Pay information not provided. Full-time. Easily apply. Develops and implements inspection and sampling techniques and quality control plans.

tolerances in metal manufacturing

5.2 Quality Management System renumbered from 5.5 . The Company's quality management system is designed to satisfy AISC standard 207-23, and includes The Quality System ensures This assures Necessary records of activities are The System is structured from top-down using this Quality Manual,

In a metal fabrication process, metal rods are produced to a specified target length of 15 feet. Suppose that the lengths are normally distributed. A quality control specialist collects a random sample of 16 rods and finds the sample mean length to . The market size of the Australian metal fabrication industry is valued at billion – a clear indication of the potential for new opportunities in our own country. Quality control processes are crucial in metal fabrication to ensure the final products meet specified standards, customer requirements and regulatory guidelines.

During steel structure fabrication a lot of issues are depended on the quality of fabrication. The lifetime of steel building can be varied depending on quality of fabrication. That’s why, NDT inspections are most important during fabrication to ensure the quality of fabrication and ensure the safety and get the maximize life time of steel . What is sheet metal fabrication? Sheet metal fabrication is a complex process of turning flat sheets of metal into products via cutting, punching, folding and assembling. Metal is cut, bent or stretched into the desired shape using special tools; band saws, cutting torches, chop saws, press brakes, oxy-acetylene torches and welding equipment.

sheet metal drawing quality

1.05 13 Random Sampling for Quality Assurance/Quality Control Projects 1.06 16 Visual Inspection 1.07 17 Tagging or Marking Materials Sampled for Projects . 3.02 57 Corrugated Metal Pipe and Metal End Sections Fabrication 3.03 60 Lane Tie and Concrete Anchor Testing 3.04 62 Load Transfer Assemblies for Transverse Joints .

Quality fabrication services are, of course, the aim of every metal fabrication job-shop. Quality assurance and quality control are, very often, touted as a company strength—and even value statement—for most shops. . (AMF) is introducing how useful the concepts of statistical sampling and Normal bell curves can be to help meeting some of . a metal washer fabrication machine makes metal washes with a Target diameter of u=10.5 millimeters. the machine has some variability Southeast standard deviation of the diameter is o= 0.003 millimeters. same machine operator inspects a random sample of 9 washers each hour quality control purposes and record the sample mean diameter, x. assuming the process .Review and understand the project specifications Take the time to thoroughly review and understand the project specifications. This task is crucial for ensuring that the fabrication process meets the required standards and the final product meets the client's expectations. Consider the materials, dimensions, design requirements, and any specific quality control measures .a) Shop drawings approved for fabrication, provided by the customer. b) Specifications and procedures for the materials. c) Specifications for fabrication, welding, finishing, delivery and other work to be performed. d) Work instructions. e) Handling instructions ; f) Reports of step by step production/fabrication;

quality metric for sheet metal

A lot of companies talk about the importance of metal fabrication quality control which, of course, is expected. But a loftier goal is to provide quality assurance, a higher level of proactive rather than reactive product .Take a look at our gallery of photos of a sample of the custom metal projects we've fabricated! top of page. 2895 S. Raritan St, Englewood, CO 80110. [email protected]. 303 - 789 - 0386. Request a Quote. Quality, custom metal fabrication and engraving. HOME. ABOUT. EMPLOYMENT;

A metal washer fabrication machine makes metal washers with a target diameter of μ = 10.5 millimeters. The machine has some variability, so the standard deviation of the diameters is σ = 0.003 millimeter. The machine operator inspects a random sample of nine washers each hour for quality control purposes and records the sample mean diameter, x̄.Buy low price Model Sampling Processing For Air Conditioning Accessories Sheet Metal Fabrication For Hardware Production by Xiamen Huimei Trade And Industry Co., Ltd., a leading supplier from China. 741 similar products are also available from global exporters.

Short-Run Metal Stamping Custom Sheet Metal Fabrication Sample Part Catalog. NAICS 332119 332322 332710. . Quality Assurance. ITAR Certification Letter AS9100D ISO-9001:2015 Certificate . Sample Part Catalog . Request for Quote . About Us. Contact Us Employment / Careers Directions Survey.

In a metal fabrication process, metal rods are produced that have an average length of 20.5 meters with a standard deviation of 2.3 meters. A quality control specialist collects a random sample of 30 rods and measures their lengths. Suppose the resulting sample mean is 19.5 meters. Which of the following statements is true? a.Since 2019, Samples Fabrication has provided quality services to clients by providing them with the professional care they deserve. Get in touch today to learn more about our Conveyor Installation, Plant Relocation, Mechanical Services and Metal Fabrication.Choosing the right alloy is crucial in metal fabrication, affecting durability, appearance, and functionality. Discover how different metals like stainless steel, aluminum, and Corten steel are tailored for specific projects to ensure long-lasting, impactful designs. Choosing the right material is crucial especially in the field of metal fabrication. The material chosen for production affects .A steel fabrication quality control checklist is vital for ensuring that steel components meet strict quality and safety standards. It covers inspections from material receipt to final product, including checks on material certifications, dimensions, welding quality, assembly alignment, and .

Metal Fabrication - Sampling Inspection All, I work for a manufacturing company that is divided up into three areas one of which is a Workshop; producing metal parts from plates. Thread by: Olivier Maudhuit , Feb 18, 2020 , 11 .The Engineering and Quality departments are responsible for the use of drawings and specifications of the latest revision. Drawing revisions are . 3.4 Sampling . Acceptance sampling procedures conform to ANSI Z1.4. Sampling to permit defects is .

quality control in metal manufacturing

metal parts quality control pdf

$210K+

sampling metal fabrication quality|quality control in metal manufacturing