automotive sheet metal forming Most autobody metal work is performed with relatively simple and traditional tools like body hammers and dollies. Add a few really straight-forward but clever tools that speed work and enhance capabilities, and you have the basis for tackling most projects in this field. 4" Cast Iron V-Groove Wheel . specifications : Rated at 600lbs Capacity ; Completely sealed bearings require no lubrication; machined from high-quality cold rolled steel, zinc plated riveted will not come loose; can be used with any V Track Steel, Aluminum OR Galvanized Track Assembly; Overall Measurement of wheel : 4"V-grooving cuts a groove that reduces the metal thickness at the bend line and allows you to produce a very small outside bend radius.

0 · sheet metal layout drawings

1 · sheet metal forming types

2 · sheet metal forming process pdf

3 · sheet metal forming press dies

4 · sheet metal forming pdf

5 · forming sheet metal by hand

6 · forming process in sheet metal

7 · bulk deformation vs sheet metal forming

It can be used in the garage, shed or closet. This affordable bracket is made with a sturdy steel construction and has a durable gray finish. Bracket is sized to fit standard lumber widths. Each bracket has six holes for extra holding power. It .

For automotive metal forming, the blank is often made of sheet metal, which can be stamped, cut or bent into a shape needed for an . In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal . For automotive metal forming, the blank is often made of sheet metal, which can be stamped, cut or bent into a shape needed for an automobile's body. Alternatively, it can be a solid block of metal in a cubical or lens-like shape. Most autobody metal work is performed with relatively simple and traditional tools like body hammers and dollies. Add a few really straight-forward but clever tools that speed work and enhance capabilities, and you have the basis for tackling most projects in this field.

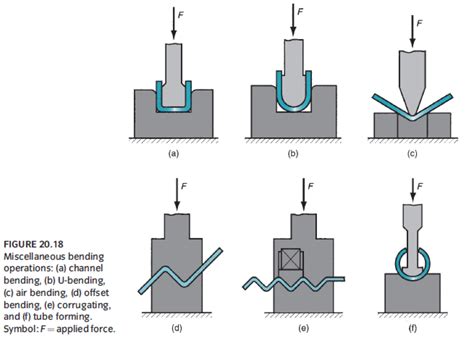

In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. Automotive Sheet Metal Forming Techniques. Forming techniques such as bending and stamping allow you to shape materials to form the right auto part. Bending. Sheet metal bending is a common technique that uses a press brake machine to deform a sheet metal and create angles and curves. The machine can apply force at predetermined points on the ..describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges Objectives Automotive manufacturers leverage sheet metal forming to fabricate body panels, chassis components, and exhaust systems, enabling the production of vehicles with optimal strength-to-weight ratios and aesthetic appeal.

Sheet metal forming is a complex process that involves the application of forces and deformations to a sheet of metal to create a desired shape. During this process, several defects can occur that can impact the quality of the final product. Sheet metal forming is a core element in the crafting of products from cars to appliances – involving skill, experience and technologically advanced tools. This article provides an insight into how this intricate process works, discussing techniques used with metals to create superior quality components. Automotive sheet metal must be durable, corrosion-resistant, and capable of withstanding the demanding conditions of the automotive industry. Selecting the correct sheet metal for the application is critical to a comprehensive design.Sheet Metal Services for Automotive Products Our team specializes in both short run and mass volume projects. From the prototype stage to the production line, we can expertly handle it all.

For automotive metal forming, the blank is often made of sheet metal, which can be stamped, cut or bent into a shape needed for an automobile's body. Alternatively, it can be a solid block of metal in a cubical or lens-like shape. Most autobody metal work is performed with relatively simple and traditional tools like body hammers and dollies. Add a few really straight-forward but clever tools that speed work and enhance capabilities, and you have the basis for tackling most projects in this field.

In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. Automotive Sheet Metal Forming Techniques. Forming techniques such as bending and stamping allow you to shape materials to form the right auto part. Bending. Sheet metal bending is a common technique that uses a press brake machine to deform a sheet metal and create angles and curves. The machine can apply force at predetermined points on the ..describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges Objectives Automotive manufacturers leverage sheet metal forming to fabricate body panels, chassis components, and exhaust systems, enabling the production of vehicles with optimal strength-to-weight ratios and aesthetic appeal.

Sheet metal forming is a complex process that involves the application of forces and deformations to a sheet of metal to create a desired shape. During this process, several defects can occur that can impact the quality of the final product. Sheet metal forming is a core element in the crafting of products from cars to appliances – involving skill, experience and technologically advanced tools. This article provides an insight into how this intricate process works, discussing techniques used with metals to create superior quality components. Automotive sheet metal must be durable, corrosion-resistant, and capable of withstanding the demanding conditions of the automotive industry. Selecting the correct sheet metal for the application is critical to a comprehensive design.

cnc precision machining service manufacturers

sheet metal layout drawings

sheet metal forming types

sheet metal forming process pdf

The Christy® product line delivers reliable, and cost effective, hand holes, valve boxes, meter boxes and vaults to the utility market. Christy® concrete products have been the preferred and trusted choice of the utility market for over 40 years.

automotive sheet metal forming|forming process in sheet metal