cnc machine regulations Regulations 1 General requirements for all machines. Scroll to Top. OSHA; . The term "gauge steel" is often used to refer to the thickness of sheet metal made of steel. Understanding these nuanced differences is vital when consulting a metal gauge chart to ensure that you're selecting the appropriate material for your endeavor.

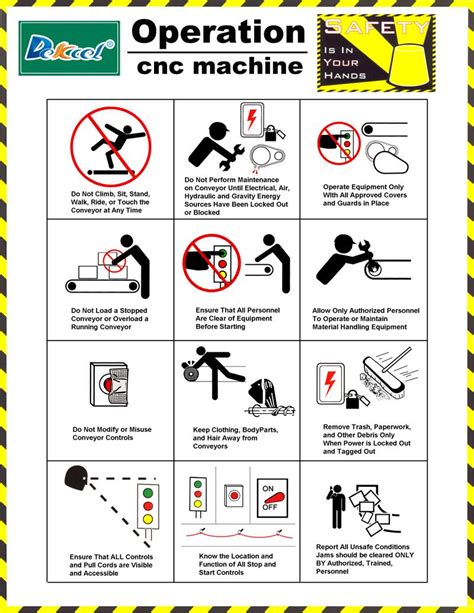

0 · safety tips for cnc machine

1 · osha safety rules for cnc

2 · osha safety for cnc machining

3 · modern cnc machine safety

4 · cnc safety rules and regulations

5 · cnc machine safety training questions

6 · cnc machine safety regulations

7 · clean cnc machine safety

Red is typically a second hot, like to have separate switches on the wall for a ceiling fan and light. Without such, it's usually left capped. The answer depends on the wiring at the switch and on what was connected to the light you removed.

safety tips for cnc machine

steel kitchen sink basen cabinets for sale

osha safety rules for cnc

General requirements for machine guards. Guards shall be affixed to the machine where possible and secured elsewhere if for any reason attachment to the machine is not possible. The guard shall be such that it does not offer an accident hazard in itself.Regulations 1 General requirements for all machines. Scroll to Top. OSHA; .OSHA requirements are set by statute, standards, and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot .

OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot .In many countries, strict personal exposure regulations and standards such as ISO Limit Values, OSHA PEL and ACGIH TLV are heavily enforced to minimize worker exposure. Containment .OSHA Regulations form the framework for Manufacturing Safety within the United States: Subpart O deals specifically with Machinery and Machine Guarding. It defines the general .

Applicable OSHA machine safety standards. The following Occupational Safety and Health Administration (OSHA) laws and regulations are most commonly applied to industrial machinery: OSHA 29 CFR 1910 General Industry . Preventing injuries and maintaining a safe workplace includes understanding potential CNC machine hazards, providing your employees with the necessary equipment training, and establishing a mandatory company .

steel light wall mounting box

Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving . To maintain CNC machine safety, operators must follow proper safety precautions and protocols. Here are some key safety measures to implement: Always keep the machine doors closed during operations to .General requirements for machine guards. Guards shall be affixed to the machine where possible and secured elsewhere if for any reason attachment to the machine is not possible. The guard shall be such that it does not offer an accident hazard in itself.OSHA requirements are set by statute, standards, and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations. Each letter constitutes OSHA's interpretation of the requirements discussed.

CNC machine operators should never begin work without proper training or the appropriate personal protective equipment (PPE). Answer the questions below to share your insights on CNC machine safety.OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations. This letter constitutes OSHA's interpretation of the requirements discussed.In many countries, strict personal exposure regulations and standards such as ISO Limit Values, OSHA PEL and ACGIH TLV are heavily enforced to minimize worker exposure. Containment and filtration are the primary solutions to mitigate employee oil mist and smoke exposure.

OSHA Regulations form the framework for Manufacturing Safety within the United States: Subpart O deals specifically with Machinery and Machine Guarding. It defines the general requirements for all machinery (1910.212). Subpart I deals specifically with Personal Protective Equipment.

Applicable OSHA machine safety standards. The following Occupational Safety and Health Administration (OSHA) laws and regulations are most commonly applied to industrial machinery: OSHA 29 CFR 1910 General Industry Regulations; OSHA 29 CFR 1910.211 Definitions; OSHA 29 CFR 1910.212 General Requirements for Guarding All Machines

Preventing injuries and maintaining a safe workplace includes understanding potential CNC machine hazards, providing your employees with the necessary equipment training, and establishing a mandatory company-wide safety program.

Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving Components or Machinery. 4. Falling Heavy Objects. 5. Heat from the Cutting Process. 1. Safety or Containment Shield. 2. Video Cameras.

To maintain CNC machine safety, operators must follow proper safety precautions and protocols. Here are some key safety measures to implement: Always keep the machine doors closed during operations to prevent exposure to moving parts.General requirements for machine guards. Guards shall be affixed to the machine where possible and secured elsewhere if for any reason attachment to the machine is not possible. The guard shall be such that it does not offer an accident hazard in itself.OSHA requirements are set by statute, standards, and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations. Each letter constitutes OSHA's interpretation of the requirements discussed. CNC machine operators should never begin work without proper training or the appropriate personal protective equipment (PPE). Answer the questions below to share your insights on CNC machine safety.

OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations. This letter constitutes OSHA's interpretation of the requirements discussed.

In many countries, strict personal exposure regulations and standards such as ISO Limit Values, OSHA PEL and ACGIH TLV are heavily enforced to minimize worker exposure. Containment and filtration are the primary solutions to mitigate employee oil mist and smoke exposure.OSHA Regulations form the framework for Manufacturing Safety within the United States: Subpart O deals specifically with Machinery and Machine Guarding. It defines the general requirements for all machinery (1910.212). Subpart I deals specifically with Personal Protective Equipment.Applicable OSHA machine safety standards. The following Occupational Safety and Health Administration (OSHA) laws and regulations are most commonly applied to industrial machinery: OSHA 29 CFR 1910 General Industry Regulations; OSHA 29 CFR 1910.211 Definitions; OSHA 29 CFR 1910.212 General Requirements for Guarding All Machines

Preventing injuries and maintaining a safe workplace includes understanding potential CNC machine hazards, providing your employees with the necessary equipment training, and establishing a mandatory company-wide safety program. Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving Components or Machinery. 4. Falling Heavy Objects. 5. Heat from the Cutting Process. 1. Safety or Containment Shield. 2. Video Cameras.

3 axis machines are the most basic with a spindle that moves up and down from side to side. 4 axis machines add a rotating axis, offering greater efficiency and flexibility. 5 axis CNC machines add a second rotating axis, offering .

cnc machine regulations|osha safety rules for cnc