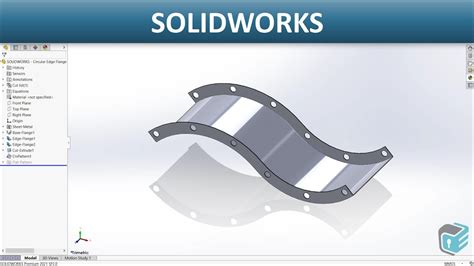

solidworks sheet metal flange Create an edge flange using the edit sketch profile and offset options. Click Edge . $89.99

0 · solidworks sheet metal edge flange

1 · solidworks miter flange tutorial

2 · solidworks miter flange sketch

3 · solidworks edge flange

4 · solidworks base flange

5 · sketch bend solidworks

6 · miter flange solidworks sheet metal

7 · miter flange in solidworks

$28.00

General edge flange characteristics include: Thickness is linked to the thickness of the sheet metal part. Sketch line of the profile must lie on the selected edge.Create an edge flange using the edit sketch profile and offset options. Click Edge .When designing sheet metal parts, the order preference for use of feature tools .Open a new part. Click Base Flange/Tab (Sheet Metal tab). Select the Front .

When you select the Base Flange/Tab feature, a sketch opens on the plane. .You can add edge flanges to one or more edges. General edge flange .Create an edge flange using the edit sketch profile and offset options. Click Edge Flange (Sheet Metal tab). Select the outer edge as shown. Drag the edge flange as shown, and click. In the .

When designing sheet metal parts, the order preference for use of feature tools are as follows: 1. Use sheet metal features such as base-flanges, edge-flanges, miter flanges, etc. 2. Use the .Open a new part. Click Base Flange/Tab (Sheet Metal tab). Select the Front Plane. A sketch opens on the Front Plane. Sketch and dimension the profile. To draw the line with its midpoint .When you select the Base Flange/Tab feature, a sketch opens on the plane. Click Base Flange/Tab on the Sheet Metal toolbar, or click Insert > Sheet Metal > Base Flange. The .

solidworks sheet metal edge flange

This video was create by BYU-Idaho for the ME 280 Mechanical Design course and demonstrates how an edge flange in the SolidWorks Sheet Metal module can be ed. Two different methods of using the EDGE FLANGE feature in Solidworks Sheet Metal. Method (1) Edit Flange Profile feature. Method (2) Edit sketch feature. Sol. How to Use SolidWorks Base Flange | SolidWorks SheetMetal Tutorial #1. Base Flange is first and basic step used to start sheet metal model. It is applicable one per part file. You can create single open, single closed or .

SOLIDWORKS 2021 Edge Flange on circular edge. To find Edge Flange you will use the Sheet Metal toolbar, search with the top right or Insert > Sheet Metal > Edge Flange. We recommend using the Sheet Metal tab for all .You can add edge flanges to one or more edges. General edge flange characteristics include: Thickness is linked to the thickness of the sheet metal part. Sketch line of the profile must lie .

creative co op metal bird house

The edges must be parallel, of the same thickness, part of the sheet metal part base, and must belong to different bodies. The option is available if you select a single edge under Flange Parameters.. The Up to Edge and Merge option .To create a sheet metal part, you sketch an open profile and use the base flange feature to create the thin feature and the bends. When you develop a sheet metal part, you generally design the part in the folded state. . Search 'Creating a Base Flange' in the SOLIDWORKS Knowledge Base. Provide feedback on this topic.The miter flange is added to the sheet metal part. Parent topicMiter Flanges. Creating Sketches for Miter Flanges. Examples of Miter Flanges at 45 Degree Angles. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this .Click Base Flange/Tab on the Sheet Metal toolbar, or click Insert > Sheet Metal > Base Flange. The controls on the Base Flange PropertyManager update according to your sketch. For example, the Direction 1 and Direction 2 boxes do not appear for a sketch with a single closed profile.

Now you create the miter flange. Mirroring the Sheet Metal Bends. When you mirror a sheet metal part, many of the bends are mirrored as well. Creating an Edge Flange. Create an edge flange using the edit sketch profile and offset options. Mirroring a Sheet Metal Feature. You can mirror sheet metal bodies as well as selected sheet metal features.The Swept Flange PropertyManager creates compound bends in sheet metal parts. To display this PropertyManager: Open a part that has an open profile sketch as the profile, and a sketch or a series of existing sheet metal edges as the path. This video was create by BYU-Idaho for the ME 280 Mechanical Design course and demonstrates how an edge flange in the SolidWorks Sheet Metal module can be ed.

You can add flanges to your sheet metal part with corners that are automatically mitered. First you add a notch to limit the propagation of the miter flange. . 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and .

Click Miter Flange (Sheet Metal tab). Select the inside vertical edge as shown to create a sketch plane normal to the selected edge with its origin at the closest endpoint of the edge. . 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the .Thickness is linked to the thickness of the sheet metal part. . For legacy parts opened with the SOLIDWORKS 2007 application, edge flange dimensions appear only after editing existing edge flanges,or rebuilding the part. Linear. You can add flanges to one or more linear edges, as well as adjust angle, position, etc.Click Base Flange/Tab (Sheet Metal toolbar) or Insert > Sheet Metal > Base Flange. Select the sketch. In the PropertyManager, under Sheet Metal Parameters, click Merge result. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and .When you add a base flange feature to a SOLIDWORKS part, the part is marked as a sheet metal part. Bends are added wherever appropriate, and sheet metal specific features are added to the FeatureManager design tree. The base flange feature is created from a sketch. The sketch can be any of the following contours:

How to Use SolidWorks Miter Flange | SolidWorks Sheet Metal Tutorial #2. Sheet metal miter flange is also like edge flange helps to add one or more flanges on base flange sheet metal part. Miter flange is slightly different from edge flange, because it needs a sketch profile of lines or arcs. And also sketch plane is always perpendicular to the .Automatic flange length dimensions will fully define those edge flange profiles with no further editing of the sketches required, thanks to a new document property for sheet metal. It can be found under the Sheet Metal > Edge Flange Options > Automatically add Flange Length dimensions to flange profiles checkbox.

Click Base Flange/Tab on the Sheet Metal toolbar, or click Insert > Sheet Metal > Base Flange. The tab is added to the sheet metal part. The tab's depth and direction are automatically set to match the parameters of the base flange feature. SOLIDWORKS Sketch Bend and Edge Flange are two very different tools that gain similar results. Why do they exist if they do the same thing? . Today we are going to decide which is the better tool to use when .

When you create edge flanges in sheet metal parts, you can create flanges with different lengths. Performance Improvements in Cosmetic Thread Features. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic .

Hi, Can anyone tell me how I can change gap distance when I make Edge Flange in Sheet metal. When I check "Use default radius I can change radius but "Gap distance" is inactive. Can anyone help me? Thanks in advance! Catalog. View in SOLIDWORKS User Forum View on Forum . Use your 3DEXPERIENCE ID to log in. . ©2002-2024 Dassault Systemes .

You can mirror sheet metal bodies as well as selected sheet metal features. Use the Right Plane to mirror the edge flange feature. The plane used to mirror the sheet metal feature must be centered between the edges of the base flange. . Search 'Mirroring a Sheet Metal Feature' in the SOLIDWORKS Knowledge Base. Provide feedback on this topic.When you create edge flanges in sheet metal parts, you can create flanges with different lengths. In the . 2025 PR1 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative. .Click Base Flange/Tab (Sheet Metal toolbar) or Insert > Sheet Metal > Base Flange. Select the sketch. In the PropertyManager, under Sheet Metal Parameters, click Merge result. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and .

solidworks miter flange tutorial

When you add a base flange feature to a SOLIDWORKS part, the part is marked as a sheet metal part. Bends are added wherever appropriate, and sheet metal specific features are added to the FeatureManager design tree. The base flange feature is created from a sketch. The sketch can be any of the following contours:

Insert Sheet Metal Edge Flange Example (VBA) This example shows how to insert a sheet metal edge flange. . click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative. To provide feedback on individual help topics, use the “Feedback on this topic .A miter flange feature adds a series of flanges to one or more edges of a sheet metal part. . SOLIDWORKS 2019 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative. .The closed corner feature adds material between sheet metal features, and includes the following capabilities: Close multiple corners simultaneously by selecting the faces for all of the corners that you want to close. Close non-perpendicular corners. Apply a closed corner to flanges with bends other than 90°. Adjust the Gap distance. The . Recently I've had a lot of trouble with sheet metal parts that won't flatten. It seems to be something to do with the base flange sketch geometry, but I can't figure out exactly what. I've attached one example, but this is a problem I'm seeing quite frequently. This part is from the large internally illuminated crest shown below.

crew metal fabrication

cremation remains metal box

Spindle Standard speed up to 10000rpm, rapid movement up to 48/48/48 m/min, cutting feed rate up to 10 m/min; Customer can choose higher speed range as per the demand. Equipped with air gun and water gun, the processing iron chips can be quickly collected into the chip box.

solidworks sheet metal flange|sketch bend solidworks