cnc machine shop parts inspection report Most of the larger corporations we do work for specify exactly what they want and most have based it on the AIAG standard. I also assume you mean 1st article inspections or . To install a junction box in the attic, you will need the following materials and tools: Junction Box: Select a junction box that meets the requirements of your electrical project, taking into account the size, material, and specifications required.

0 · inspection report for cnc parts

1 · cnc machining inspection

2 · cnc machined parts inspection

3 · cnc machined inspection report

4 · cnc inspection system

5 · cnc inspection report template

6 · cnc inspection process

7 · cnc finish inspection

I need to connect two 8/3 wires together in a junction box. What is the correct type of connector to do this? The two hardware stores I went to had nothing for 8 gauge wires.

inspection report for cnc parts

We presently inspect parts, write down the findings on a printed test report and scan them into a customer archive. We would like to be able to eliminate the paper and use a . At present, how about the parts inspection report in the machining field? VMT focuses on high-precision CNC machining . We will share the inspection reports of conventional machined parts for you.

For our commercial customers, we will do a Final Verification which consists of paper work review and visual inspection if parts have a finish. The critical customers, such as .

wheeled metal tool boxes

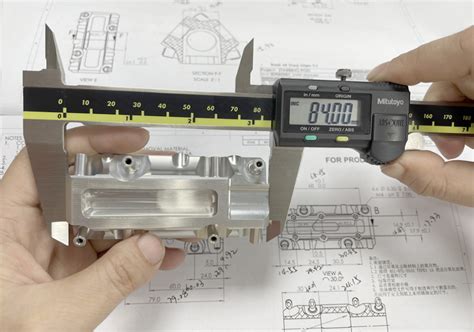

By utilizing state-of-the-art equipment and systematic inspection procedures, we ensure that every CNC machined part you receive is of the highest quality, meeting both your specifications and industry standards. Most of the larger corporations we do work for specify exactly what they want and most have based it on the AIAG standard. I also assume you mean 1st article inspections or . Explore quality control and inspection technologies for CNC machined parts. Learn how to use different measurement tools to ensure quality in CNC machining. Inspection Methods for CNC Machined Parts. We’ve been primarily looking at quality control, but what inspection methods are used in CNC production? Let’s explore the different CNC inspection equipment and .

We offer six different inspection options for our CNC and sheet fabrication services. The inspection options are described in more detail below. For an example of a Xometry . In order to meet customer expectations, trade standards and industry regulations, SANS Machining uses different measuring instruments and tools to control the quality of CNC machined parts produced in our machining .

PDF Template, Machine inspection report to ensure all manufacturing tasks have been completed We presently inspect parts, write down the findings on a printed test report and scan them into a customer archive. We would like to be able to eliminate the paper and use a tablet to enter the information directly into an Excel spreadsheet.

At present, how about the parts inspection report in the machining field? VMT focuses on high-precision CNC machining . We will share the inspection reports of conventional machined parts for you. For our commercial customers, we will do a Final Verification which consists of paper work review and visual inspection if parts have a finish. The critical customers, such as safety products or aerospace, or if customer requires it will require a . By utilizing state-of-the-art equipment and systematic inspection procedures, we ensure that every CNC machined part you receive is of the highest quality, meeting both your specifications and industry standards. Most of the larger corporations we do work for specify exactly what they want and most have based it on the AIAG standard. I also assume you mean 1st article inspections or PPAP.

Explore quality control and inspection technologies for CNC machined parts. Learn how to use different measurement tools to ensure quality in CNC machining. Inspection Methods for CNC Machined Parts. We’ve been primarily looking at quality control, but what inspection methods are used in CNC production? Let’s explore the different CNC inspection equipment and processes that .

We offer six different inspection options for our CNC and sheet fabrication services. The inspection options are described in more detail below. For an example of a Xometry dimensional inspection report with a correlated ballooned print, please refer to our Sample Inspection Documents page.

In order to meet customer expectations, trade standards and industry regulations, SANS Machining uses different measuring instruments and tools to control the quality of CNC machined parts produced in our machining workshop.

PDF Template, Machine inspection report to ensure all manufacturing tasks have been completed We presently inspect parts, write down the findings on a printed test report and scan them into a customer archive. We would like to be able to eliminate the paper and use a tablet to enter the information directly into an Excel spreadsheet. At present, how about the parts inspection report in the machining field? VMT focuses on high-precision CNC machining . We will share the inspection reports of conventional machined parts for you. For our commercial customers, we will do a Final Verification which consists of paper work review and visual inspection if parts have a finish. The critical customers, such as safety products or aerospace, or if customer requires it will require a .

By utilizing state-of-the-art equipment and systematic inspection procedures, we ensure that every CNC machined part you receive is of the highest quality, meeting both your specifications and industry standards. Most of the larger corporations we do work for specify exactly what they want and most have based it on the AIAG standard. I also assume you mean 1st article inspections or PPAP. Explore quality control and inspection technologies for CNC machined parts. Learn how to use different measurement tools to ensure quality in CNC machining.

Inspection Methods for CNC Machined Parts. We’ve been primarily looking at quality control, but what inspection methods are used in CNC production? Let’s explore the different CNC inspection equipment and processes that . We offer six different inspection options for our CNC and sheet fabrication services. The inspection options are described in more detail below. For an example of a Xometry dimensional inspection report with a correlated ballooned print, please refer to our Sample Inspection Documents page.

In order to meet customer expectations, trade standards and industry regulations, SANS Machining uses different measuring instruments and tools to control the quality of CNC machined parts produced in our machining workshop.

what type of steel is a box beam made of

Engineering Supplies and Book Store : - Design Engineering Productivity 3D .

cnc machine shop parts inspection report|cnc inspection report template