best cnc machine for stainless steel Stainless steel CNC machining is an accurate and efficient machining process that uses CNC machines to shape, fabricate and cut stainless steel parts. Numerous industries use stainless steel because it is durable and . Grand Brass Lamp Parts has the largest Selection of lamp Sockets and Bulb .

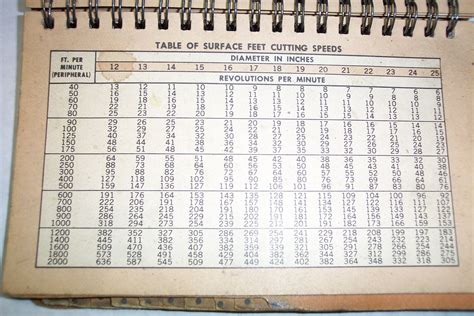

0 · surface footage for 304 stainless

1 · high speed milling stainless steel

2 · coolant for drilling stainless steel

3 · cnc machining stainless steel 420

4 · 400 series stainless steel machinability

5 · 304 stainless steel machining recommendations

6 · 304 stainless steel cutting speed

7 · 15 5 stainless steel machinability

Looking for custom aluminum parts? Look no further than Anebon! We are a factory that specializes in CNC milling of aluminum parts. Contact us today for wholesale pricing and high-quality products.

surface footage for 304 stainless

What tooling is best for machining 304? Tialn coated tools or carbide? I just ruined a brand new 7 flute TIALN coated bit. I have been trying do high speed approach I stole from Volumills site but it obviously did not work as I cooked the bit! Using mastercam to program .

High Efficiency Milling (HEM) can be a very effective machining technique in stainless steels if the correct tools are selected. Chipbreaker roughers would make an . Granted, there are lots of end mill manufacturers but these are my prefs (with order of preference) for stainless; namely 316L, 13-8. the tougher stuff. 1. Hitachi - Epoch CS. 2. .Generally speaking, uncoated carbide tools work well in general-purpose machining, while those coated with titanium nitride (TiN) or titanium carbonitride (TiCN), among others, enhance tool .

make a hole in metal box

high speed milling stainless steel

Stainless steel CNC machining is an accurate and efficient machining process that uses CNC machines to shape, fabricate and cut stainless steel parts. Numerous industries use stainless steel because it is durable and .

Stainless steel is one of the most commonly used machining materials. Stainless steel machining creates products and tools for every sector out there. Stainless steel machining is not as easy as materials like wood. . Many stainless steel items are produced via CNC machining, a versatile manufacturing method that leverages the precision of computer-guided mills, drills, lathes, and other cutting tools to efficiently and cost-effectively . This article will provide a detailed, professional overview of the best practices for machining stainless steel, focusing on optimizing machining methods and selecting the most . Learn about the five main types of Stainless Steel and how to choose the correct grade for your CNC machining project. Stainless steel is an incredibly versatile metal and is often used for CNC (Computer Numerical .

What tooling is best for machining 304? Tialn coated tools or carbide? I just ruined a brand new 7 flute TIALN coated bit. I have been trying do high speed approach I stole from Volumills site but it obviously did not work as I cooked the bit! Using mastercam to program and DNCing the code. Running flood coolant.

The best CNC machine is calibrated to your particular applications and capabilities. With that being said, consider each job you plan to do from multiple angles. Consider accuracy, speed, safety, and maintenance. High Efficiency Milling (HEM) can be a very effective machining technique in stainless steels if the correct tools are selected. Chipbreaker roughers would make an excellent choice, in either 5 or 7 flute styles, while standard 5-7 flute, variable pitch end mills can also perform well in HEM toolpaths. Granted, there are lots of end mill manufacturers but these are my prefs (with order of preference) for stainless; namely 316L, 13-8. the tougher stuff. 1. Hitachi - Epoch CS. 2. OSG - SUS-series. 3. Destiny Tool - Raptor DVH. You can run any of these at 600-700 sfm with HS toolpaths; axial @ 1.5D, radial @ .05-.1D.

Generally speaking, uncoated carbide tools work well in general-purpose machining, while those coated with titanium nitride (TiN) or titanium carbonitride (TiCN), among others, enhance tool life and reduce friction. Stainless steel CNC machining is an accurate and efficient machining process that uses CNC machines to shape, fabricate and cut stainless steel parts. Numerous industries use stainless steel because it is durable and resistant to corrosion. Stainless steel is one of the most commonly used machining materials. Stainless steel machining creates products and tools for every sector out there. Stainless steel machining is not as easy as materials like wood. Stainless steel has a high hardness and tensile strength.

making a tight 90 degree angle with a junction.box

Many stainless steel items are produced via CNC machining, a versatile manufacturing method that leverages the precision of computer-guided mills, drills, lathes, and other cutting tools to efficiently and cost-effectively create precise, repeatable parts.

This article will provide a detailed, professional overview of the best practices for machining stainless steel, focusing on optimizing machining methods and selecting the most appropriate tools to achieve higher precision, longer tool life, and improved productivity.

Learn about the five main types of Stainless Steel and how to choose the correct grade for your CNC machining project. Stainless steel is an incredibly versatile metal and is often used for CNC (Computer Numerical Control) Machining and CNC turning in the aerospace, automotive and marine industries.

What tooling is best for machining 304? Tialn coated tools or carbide? I just ruined a brand new 7 flute TIALN coated bit. I have been trying do high speed approach I stole from Volumills site but it obviously did not work as I cooked the bit! Using mastercam to program and DNCing the code. Running flood coolant. The best CNC machine is calibrated to your particular applications and capabilities. With that being said, consider each job you plan to do from multiple angles. Consider accuracy, speed, safety, and maintenance. High Efficiency Milling (HEM) can be a very effective machining technique in stainless steels if the correct tools are selected. Chipbreaker roughers would make an excellent choice, in either 5 or 7 flute styles, while standard 5-7 flute, variable pitch end mills can also perform well in HEM toolpaths. Granted, there are lots of end mill manufacturers but these are my prefs (with order of preference) for stainless; namely 316L, 13-8. the tougher stuff. 1. Hitachi - Epoch CS. 2. OSG - SUS-series. 3. Destiny Tool - Raptor DVH. You can run any of these at 600-700 sfm with HS toolpaths; axial @ 1.5D, radial @ .05-.1D.

Generally speaking, uncoated carbide tools work well in general-purpose machining, while those coated with titanium nitride (TiN) or titanium carbonitride (TiCN), among others, enhance tool life and reduce friction. Stainless steel CNC machining is an accurate and efficient machining process that uses CNC machines to shape, fabricate and cut stainless steel parts. Numerous industries use stainless steel because it is durable and resistant to corrosion.

Stainless steel is one of the most commonly used machining materials. Stainless steel machining creates products and tools for every sector out there. Stainless steel machining is not as easy as materials like wood. Stainless steel has a high hardness and tensile strength. Many stainless steel items are produced via CNC machining, a versatile manufacturing method that leverages the precision of computer-guided mills, drills, lathes, and other cutting tools to efficiently and cost-effectively create precise, repeatable parts. This article will provide a detailed, professional overview of the best practices for machining stainless steel, focusing on optimizing machining methods and selecting the most appropriate tools to achieve higher precision, longer tool life, and improved productivity.

coolant for drilling stainless steel

Find your aluminum junction box easily amongst the 153 products from the leading brands (WISKA, HENSEL, NBC Elettronica, .) on DirectIndustry, the industry specialist for your professional purchases.

best cnc machine for stainless steel|surface footage for 304 stainless